Thanks for the kind comments.

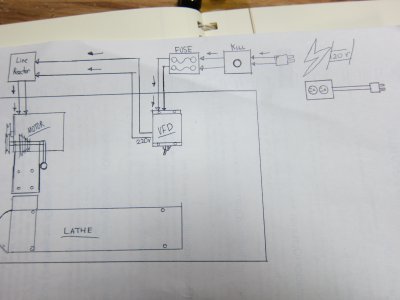

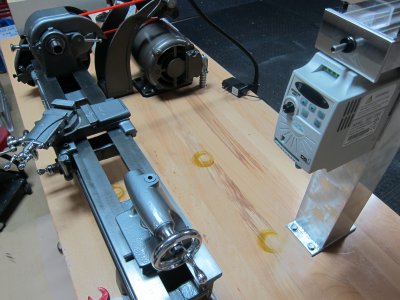

Unfortunately, I was not able to use the old motor, as when I converted the system to a variable frequency drive (VFD), I moved from 110v to 220v. So I'll sell it, the switch and riser on ebay as I will not need it again.

The cost was nearly $800, but it could have been done a lot cheaper. Not using a nasa welder, not building a sophisticated riser, using top wiring, new lead-screw and half-nut, and a few other things could have shaved $400 off. I already had the table so that was nice.

And in building it, I did so using heavier wiring than necessary for the motor used etc so I would have the option to drop another slightly larger lathe in its place. A Southbend 9 or equivalent would be very appropriate, and the table has to space to acommodate it. I planned to grow into a larger unit if I so desire. That said, I'll have some time to enjoy this one.

Like most things in life, it was a lot more work than I expected, and cost more than I anticipated.