- Joined

- Jun 29, 2014

- Messages

- 197

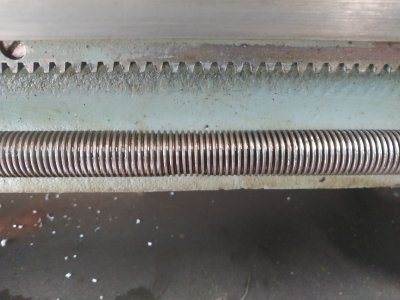

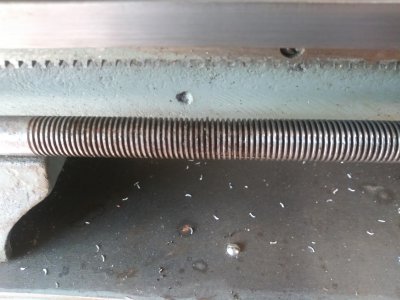

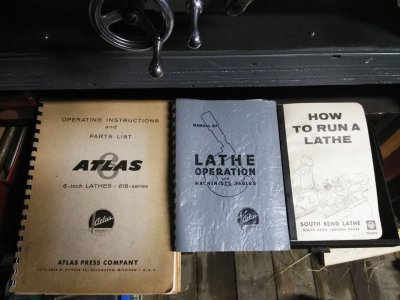

I made what I believe to be a really good deal the other day on a 618 lathe. It looks good, paint included, and runs really smooth. Came with a good selection of cutters and tool holders. Decent rolling stad and tool box. The only thing I found wrong is in the lead screw. I put it in forward or reverse and engage the thread dial and it works normally. But, if I put it in backgear the thread dial does not move nor does the carriage. I am in hopes the lead screw and or half nuts are dirty. Hope to take it apart today. According to printed catalogue I saw the lead screw is 1/2” x 16 tip acme thread. I cannot fing a die to chase threads to clean them. Anybody got a solution?

Attachments

-

6350BB92-9EC9-43DE-96F5-2588120C6AC7.jpeg119.4 KB · Views: 58

6350BB92-9EC9-43DE-96F5-2588120C6AC7.jpeg119.4 KB · Views: 58 -

9A175270-460B-4E75-8C9A-2ADAA396D002.jpeg101.7 KB · Views: 60

9A175270-460B-4E75-8C9A-2ADAA396D002.jpeg101.7 KB · Views: 60 -

63CF0D08-9635-41FC-9441-01153263226E.jpeg98.3 KB · Views: 59

63CF0D08-9635-41FC-9441-01153263226E.jpeg98.3 KB · Views: 59 -

61EF7633-FB9A-4FAC-B64F-F4360FD5D731.jpeg102.1 KB · Views: 58

61EF7633-FB9A-4FAC-B64F-F4360FD5D731.jpeg102.1 KB · Views: 58 -

3569B62B-397D-48D5-A1D5-5EDE9ABEB7CB.jpeg89.3 KB · Views: 52

3569B62B-397D-48D5-A1D5-5EDE9ABEB7CB.jpeg89.3 KB · Views: 52 -

A921AD32-146A-4B28-A7DB-F437B254D9C2.jpeg114.9 KB · Views: 58

A921AD32-146A-4B28-A7DB-F437B254D9C2.jpeg114.9 KB · Views: 58