- Joined

- Dec 25, 2011

- Messages

- 10,511

Tim,

Please confirm that the LOA of the bed ways is about 42".

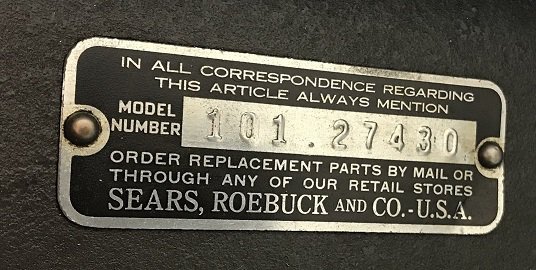

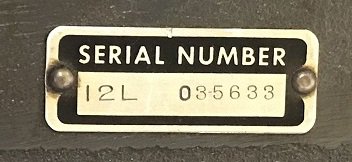

That is the earliest 10" serial number so far reported. And the only 10C. Attached below is a catalog page with a photo showing what was probably originally shipped. Note no change gear guard, motor switch, back gears, or lead screw. The half nut operating lever is present but is in the DOWN position because there is nothing behind to hold it up. A PO, probably the OO, bought the lathe and then within less than a year, bought the back gears, change gear system, etc. to bring it up to what I think at the time would have just been called a 1042 but might have been a 1042D.

Your switch box is original, at least to the add-ons, but the switch mounting plate and switches are not original. There was only one switch, and it was the style commonly known as a wall switch (or light switch). I would guess that the second switch on your machine is probably a reversing switch.

I agree that it probably dates from 1934.

It is interesting to note that according to the catalog prices, the total cost with the added upgrades was $106.00. If he had bought it that way to begin with, the price would have been $105.50.

Please confirm that the LOA of the bed ways is about 42".

That is the earliest 10" serial number so far reported. And the only 10C. Attached below is a catalog page with a photo showing what was probably originally shipped. Note no change gear guard, motor switch, back gears, or lead screw. The half nut operating lever is present but is in the DOWN position because there is nothing behind to hold it up. A PO, probably the OO, bought the lathe and then within less than a year, bought the back gears, change gear system, etc. to bring it up to what I think at the time would have just been called a 1042 but might have been a 1042D.

Your switch box is original, at least to the add-ons, but the switch mounting plate and switches are not original. There was only one switch, and it was the style commonly known as a wall switch (or light switch). I would guess that the second switch on your machine is probably a reversing switch.

I agree that it probably dates from 1934.

It is interesting to note that according to the catalog prices, the total cost with the added upgrades was $106.00. If he had bought it that way to begin with, the price would have been $105.50.

Attachments

Last edited: