Boomer,

This "is" the dedicated Atlas forum.

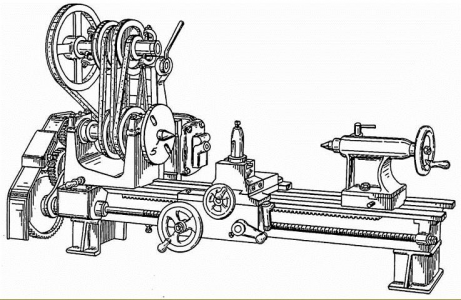

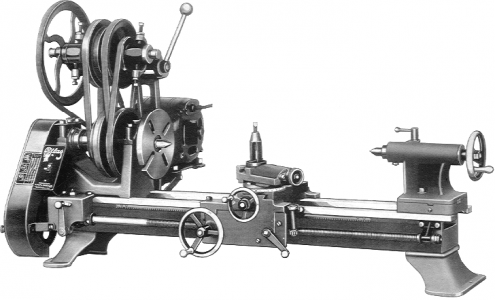

If your grandfather bought it used in 1937. it wasn't very used as the first 9" was made around 1932. We don't know s lot about the 9" as only a few have been reported here. But I would suggest that you clear all of the junk away from it and stand something like a sheet of plywood up behind it so that we only see the lathe and re-shoot the photo, with some close-ups, too..

On the question of run-out, I would first suggest that you confirm that the chuck jaws are all in their correct slots and that the three jaws all belong to that chuck. You cannot swap jaws to another chuck. Near each jaw slot on the OD of the chuck body there should be stamped a single number, 1, 2 or 3. On the side of each jaw will be stamped 1, 2 or 3. Confirm that the digit on each jaw matches the slot number. There should also be two sets of three jaws each for that one chuck. One set will have the tallest jaw nearest to the spindle. Those are sometimes called the ID jaws or inside jaws. The other set are just the opposite. And you cannot reverse the jaws on a 3-jaw.

In Downloads, you will find one Craftsman and no Atlas parts lists. However, about the only differences between the two different badges are the legs under the bed. For some reason, Sears seemed to have a "thing" about legs.

I will also mention that full access to Downloads requires Donor status (any level).

On a serial number, I think that Atlas followed the same procedure for the 9" that they did for the 10" and early 12". So you should find the serial number stamped into the top of the right end of the front way, in the narrow strip between where the carriage ran and where the tailstock runs. Atlas made about 5000 of the 9" Atlas lathes. Whether they had a different pool of numbers for Sears and for Atlas, we don't really know, but they probably did. Does the lathe have any badges on it?