-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

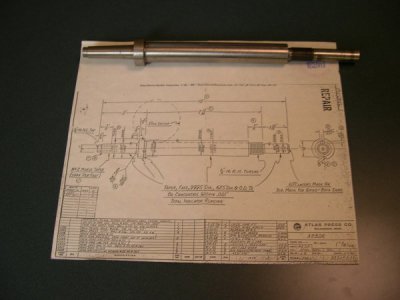

Atlas Mfc Mill Arbor Drawing ?

- Thread starter Mondo

- Start date

- Joined

- Nov 2, 2013

- Messages

- 962

I mentioned some time ago that I'd get some pics so today I got it done. I also added some pics of the spacers because there had been a discussion about the keys for the cutters and not in the spacers.

the bottom arbor is from tools4cheap when he was closing up. That nut doesn't have the counterbore and only 2 flutes to tighten the nut. Hope you find it interesting.

the bottom arbor is from tools4cheap when he was closing up. That nut doesn't have the counterbore and only 2 flutes to tighten the nut. Hope you find it interesting.

It would be an easy task to cut a recess in the black nuts that came with the arbors from Mr. Beck.

My attitude for key notches in the spacers is you really don't need more than a few short ones that are notched. Put one on each side of any thin cutter like slitting saws and use short stubby keys. It is far easier to keep a selection of key stock in assorted lengths than it is to be broaching key slots in all the spacers, especially the longer ones. Other than convenience of having one on each side of a thin cutter the spacers have no need for key slots.

Spiral_Chips

My attitude for key notches in the spacers is you really don't need more than a few short ones that are notched. Put one on each side of any thin cutter like slitting saws and use short stubby keys. It is far easier to keep a selection of key stock in assorted lengths than it is to be broaching key slots in all the spacers, especially the longer ones. Other than convenience of having one on each side of a thin cutter the spacers have no need for key slots.

Spiral_Chips

- Joined

- Nov 2, 2013

- Messages

- 962

I agree with having a couple spacers only that have a key slot. Say 2 at 1/4" wide and 2 at 1/2" wide.

This would pretty much let you cover all the combinations of various width cutters and like you say just have a small variety of keystock in different lengths.

But so far in anything I've done, I've never had a cutter spin free and I've only inserted a key once and that cutter was wide enougth to cover the short key I had used.

This would pretty much let you cover all the combinations of various width cutters and like you say just have a small variety of keystock in different lengths.

But so far in anything I've done, I've never had a cutter spin free and I've only inserted a key once and that cutter was wide enougth to cover the short key I had used.

- Joined

- May 17, 2012

- Messages

- 104

34_40, thank you for the pictures. They make the nut issues very clear. The points about the spacers are very good. Making the short ones keyed is a much simpler task than the long ones. Thanks for the insight, guys..

Back to the taper. I finally got the pulley from the vertical head off my mill, and put the arbor driver nut on. When I put a commercial morse taper into my mill (the bore has been spun, so this all has some +/- to it), I measure .697 taper diameter at the face of the arbor driver. With a standard taper that ends at .700, that would give (.700-.697)/.04995=.06006 or a little under 1/16" spacing between the face of the arbor driver and the driving flange on the arbor if the MT2 intersects the arbor flange at a diameter of .700. This suggests a full length taper should work.

Rob's photo makes the length of the taper look to be 2 7/16, not the 2 9/16 from the books. I also keep forgetting the straight section on the end of the tapers. I need to get that into the drawings as well. I'm in the midst of making a tumbler pivot shaft assembly right now, but I think I might try making a taper after that. The compund travel is only 2 1/4", so that should get interesting. I see a file and bluing in m future. I still am tossing around the idea of using a commercial taper with a thread screwed into a home made arbor. An ebay seller named thirddevel sells a MT2 x 1/2-20 arbor with a 3/8-16 drawbar thread. It's kind of expensive at $21.90, but much cheaper than the real Jacobs arbors.

Back to the taper. I finally got the pulley from the vertical head off my mill, and put the arbor driver nut on. When I put a commercial morse taper into my mill (the bore has been spun, so this all has some +/- to it), I measure .697 taper diameter at the face of the arbor driver. With a standard taper that ends at .700, that would give (.700-.697)/.04995=.06006 or a little under 1/16" spacing between the face of the arbor driver and the driving flange on the arbor if the MT2 intersects the arbor flange at a diameter of .700. This suggests a full length taper should work.

Rob's photo makes the length of the taper look to be 2 7/16, not the 2 9/16 from the books. I also keep forgetting the straight section on the end of the tapers. I need to get that into the drawings as well. I'm in the midst of making a tumbler pivot shaft assembly right now, but I think I might try making a taper after that. The compund travel is only 2 1/4", so that should get interesting. I see a file and bluing in m future. I still am tossing around the idea of using a commercial taper with a thread screwed into a home made arbor. An ebay seller named thirddevel sells a MT2 x 1/2-20 arbor with a 3/8-16 drawbar thread. It's kind of expensive at $21.90, but much cheaper than the real Jacobs arbors.

- Joined

- May 17, 2012

- Messages

- 104

That would save a lot of fussy machining. I could drill and tap the end for 1/2-20, extend the keyway to the end of the drill rod and make the drive flange as a separate piece, keyed to the shaft. Buy the taper, and only turn the threads and end bearing.

Thanks for the idea!

Thanks for the idea!

- Joined

- Dec 25, 2011

- Messages

- 10,511

Although my 7.8" arbor is still in the crate, I found where I had put the factory 1" one and looked at all of the spacers that I had gotten with it plus a second group from another source. What I found generally agrees with 34_40's photos. All of the 1/2" and thinner spacers are keyed. Some of the thicker ones are and some are not.