- Joined

- Mar 20, 2024

- Messages

- 64

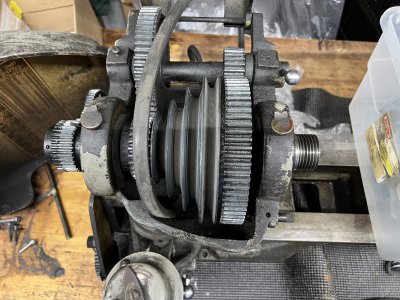

Picked up this Atlas TH42 last week. I’ve started assessing what I’ve gotten myself into and probably shoulda waited for something less needy. But I’m in it now so let’s see where it goes. This is my first lathe and my first attempt at taking anything like this apart to clean up and refresh.

Off the bat I know I need a new motor, belts and some wiring. And a lot of cleaning stuff.

Off the bat I know I need a new motor, belts and some wiring. And a lot of cleaning stuff.