- Joined

- Mar 26, 2014

- Messages

- 1,576

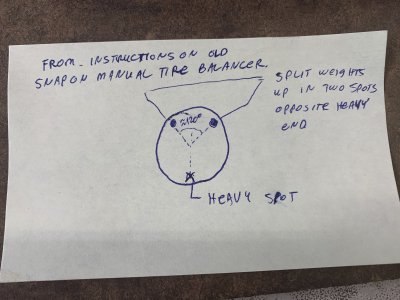

Looking for suggestions on balancing a 20” diameter cast iron pulley. I trued up these two pulleys and when they are mounted to. The shaft and bearing, it will always turn to the same position.

What is the Mandrel on the fence method?

Short of drilling holes, can I epoxy some lead to the opposite side?

Also is there a way to tell how much to heavy it is on the unbalanced side?

Thanks

Martin

What is the Mandrel on the fence method?

Short of drilling holes, can I epoxy some lead to the opposite side?

Also is there a way to tell how much to heavy it is on the unbalanced side?

Thanks

Martin