- Joined

- Jul 26, 2011

- Messages

- 4,142

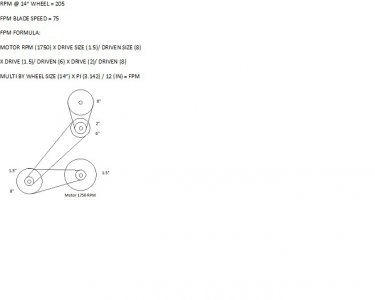

250 FPM is still pretty fast. If you EVER cut tool steel,you have to get the speed down to 75 FPM,or you will quickly ruin another blade. In fact,even at a low speed,01 tool steel can suddenly harden just from the heat of cutting. This hardening is only a few thou. deep,but it is quite enough to strip the teeth off your blade. You need to go 75 FPM,and KEEP the tool steel moving. If you hesitate,it may allow heat from friction to build up and surface harden the steel.