New member here, I'd love to get some feedback and help me build my "machine shop". It's pretty much ground 0, I need to pick and get everything.

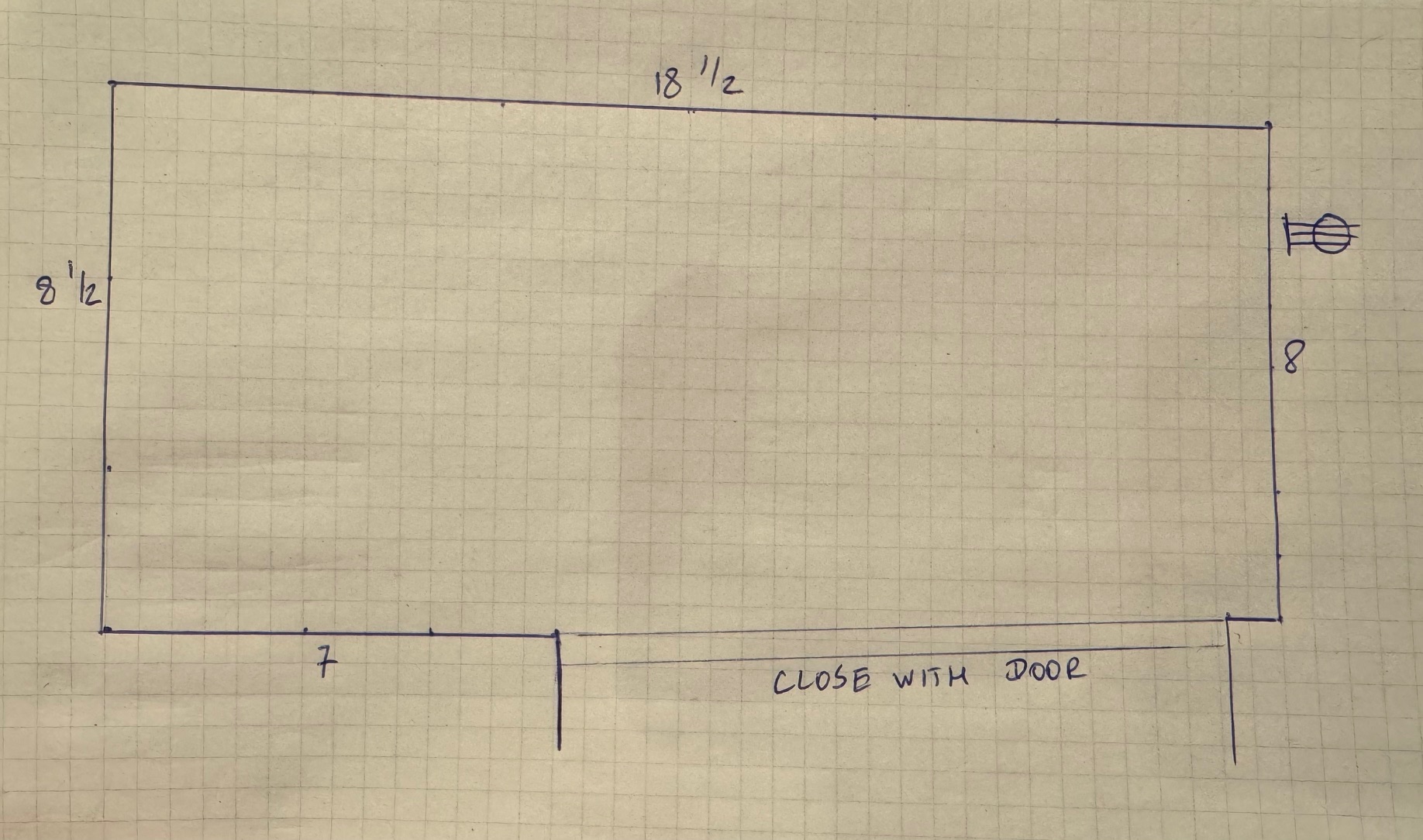

Currently I am in a process of finishing basement and the room on a picture is what I can work with (18x8). Ideally I want to get lathe, mill, belt grinder, and perhaps some bench space in there. So considerations need to be taken when positioning machines so I don't grind next to the lathe. Any suggestions onto best layout welcome.

Also, since it's a basement - I kind of ruled out any "old iron" choices. I am pretty much set on getting PM 1340GT or PM 1236T. I don't know much, but I don't want to "grow out" of whatever I get. This is just a hobby also. I think safe movers will be able to get 1000lb lathe down basement stairs (exterior concrete steps)

Below is Q/A from document posted in this sub-forum:

Stainless, hard alloys, up to 12"

Budget $5-10k

Will be setup in basement

Single phase 220V

There better not be anything wrong with late, but few dents and scratches OK

Will be set on factory stand/mount or I will fab one from metal profile

Lathe will need to be delivered and then moved into my garage.

I will need all of the tooling

What is Your Knowledge & Experience with Lathes?

I had 9x20 HF lathe, did some modifications to it (VFD, stronger toolpost base, etc). I know basics but never did threading for example.

I know theory (mechanical engineering degree and some classes) but it's just for DIY.

Lathe Functions?

In addition to a powered spindle and manual longitudinal and cross feeds, what functions do you have in mind? Do you need to cut threads (inch? metric? both?)? Do you require power feeds (longitudinal? cross?)? Do you require a taper attachment and/or DRO?

I'd love to have very good slow feeds, ability to work with hard/stainless. Metric threads (probably no imperial). DRO would be nice.

Type/Size of Intended Workpieces?

General motorcycle widgets, tooling for working on cars/motorcycles. Would be nice to be able to make high precision parts from hard materials.

Physical Size of Lathe?

See drawing

What Electrical Power is Available?

Single phase 220V residential

Market Conditions in Your Area?

St Louis, MO. Haven't really see anything that caught my eye.

Currently I am in a process of finishing basement and the room on a picture is what I can work with (18x8). Ideally I want to get lathe, mill, belt grinder, and perhaps some bench space in there. So considerations need to be taken when positioning machines so I don't grind next to the lathe. Any suggestions onto best layout welcome.

Also, since it's a basement - I kind of ruled out any "old iron" choices. I am pretty much set on getting PM 1340GT or PM 1236T. I don't know much, but I don't want to "grow out" of whatever I get. This is just a hobby also. I think safe movers will be able to get 1000lb lathe down basement stairs (exterior concrete steps)

Below is Q/A from document posted in this sub-forum:

Stainless, hard alloys, up to 12"

Budget $5-10k

Will be setup in basement

Single phase 220V

There better not be anything wrong with late, but few dents and scratches OK

Will be set on factory stand/mount or I will fab one from metal profile

Lathe will need to be delivered and then moved into my garage.

I will need all of the tooling

What is Your Knowledge & Experience with Lathes?

I had 9x20 HF lathe, did some modifications to it (VFD, stronger toolpost base, etc). I know basics but never did threading for example.

I know theory (mechanical engineering degree and some classes) but it's just for DIY.

Lathe Functions?

In addition to a powered spindle and manual longitudinal and cross feeds, what functions do you have in mind? Do you need to cut threads (inch? metric? both?)? Do you require power feeds (longitudinal? cross?)? Do you require a taper attachment and/or DRO?

I'd love to have very good slow feeds, ability to work with hard/stainless. Metric threads (probably no imperial). DRO would be nice.

Type/Size of Intended Workpieces?

General motorcycle widgets, tooling for working on cars/motorcycles. Would be nice to be able to make high precision parts from hard materials.

Physical Size of Lathe?

See drawing

What Electrical Power is Available?

Single phase 220V residential

Market Conditions in Your Area?

St Louis, MO. Haven't really see anything that caught my eye.