- Joined

- Jun 7, 2016

- Messages

- 361

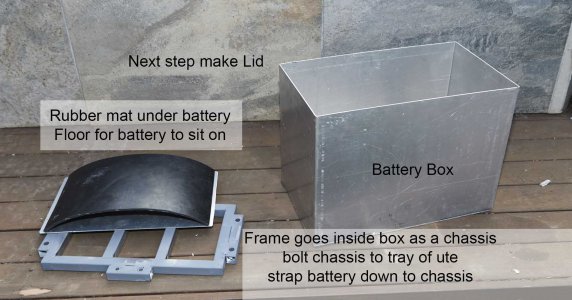

Well spent another day working on a custom battery box for my son's new ute.

Gave me a chance to clear the dust off the small pan brake. It worked really well for this job.

I opted to build a sort of chassis for the battery to be secured to, as the 2mm aluminium box has no strength to deal with a heavy battery.

Still got some more work to do on that with some tie down rods and wing nuts.

anyway there you have it.

Mal

Gave me a chance to clear the dust off the small pan brake. It worked really well for this job.

I opted to build a sort of chassis for the battery to be secured to, as the 2mm aluminium box has no strength to deal with a heavy battery.

Still got some more work to do on that with some tie down rods and wing nuts.

anyway there you have it.

Mal