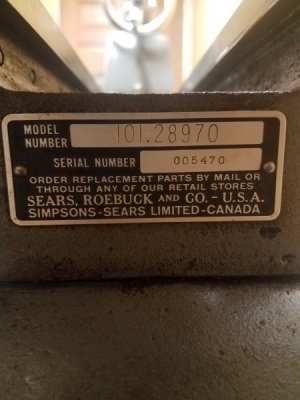

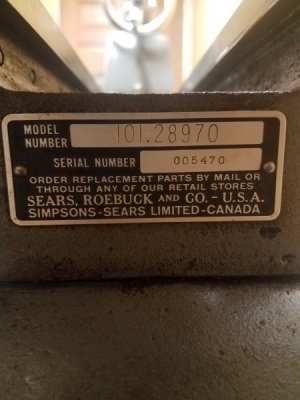

Here's the machine in question and a picture of the model#

I got it a few weeks ago, and have been cleaning it up. I have a question on the pulley bearing going to the headstock.

Those are the only 2 places I can see that would provide any kind of lubrication, but to me they look like set screws to lock the pulleys onto the shaft. Is that a sealed bearing, or am I missing something?

And another question, are these oil ports for the shaft inside the motor, if so do I just have to pry the rubber off to get to it? Or just leave it alone.

I'll most likely have other questions as I go along as well. Thanks

I got it a few weeks ago, and have been cleaning it up. I have a question on the pulley bearing going to the headstock.

Those are the only 2 places I can see that would provide any kind of lubrication, but to me they look like set screws to lock the pulleys onto the shaft. Is that a sealed bearing, or am I missing something?

And another question, are these oil ports for the shaft inside the motor, if so do I just have to pry the rubber off to get to it? Or just leave it alone.

I'll most likely have other questions as I go along as well. Thanks