- Joined

- Mar 3, 2017

- Messages

- 744

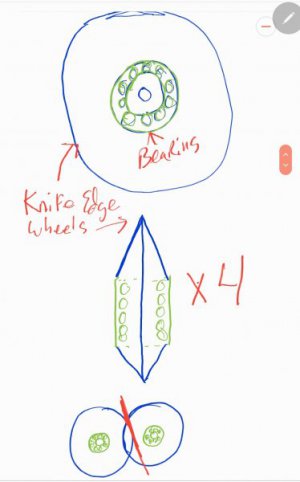

I would like to build a grinding wheel balancer....

My concern is a free turning bearing that won't break the bank.

A polished steel shaft, and a plastic bearing, with a little compressed air, will make a good low-friction support.

You don't need vibration resistance, or strength, just a way to put a bit of clean air between the solid parts.

Commercial gizmos use porous journals, it seems. I'd think two plastic bushings with air forced into the gap between

would float a shaft and modest size grinding wheel.