Hello all, I’m sure it’s been covered here however I can’t seem to find the answers I’m looking for. So I have my Chinese mill broken down and have remove the spindle bearings and races from the shaft and from the quill to facilitate measuring. I’m wanting to upgrade the spindle bearing to an angular contact style bearing setup. At the moment she has the cheap Chinese taper bearings. I have done some research and it seems SKF makes some good ones however the width is not exact, so I’m guessing that I will need to bore out the quill to receive the wider bearing. Correct me if I’m wrong. Also I would love some insight on the various SKF bearings offered. They range in price from $50 on up to $150. Which ones do I need and what’s the difference in price all about? Thanks in advance

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bearings

- Thread starter Pevehouse

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,335

The original bearings should have some standard metric numbers on them I would think

that you can use to cross reference them. SKF is good but there are other good brands. Timken are always good if they have your size

Nachi is also good, it's a Japanese company

Higher price usually means better quality and higher precision, generally

For a Chinese mill you can economize a little bit- you don't need the most expensive stuff

that you can use to cross reference them. SKF is good but there are other good brands. Timken are always good if they have your size

Nachi is also good, it's a Japanese company

Higher price usually means better quality and higher precision, generally

For a Chinese mill you can economize a little bit- you don't need the most expensive stuff

Last edited:

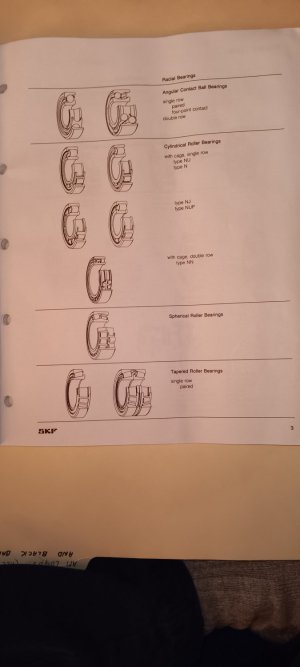

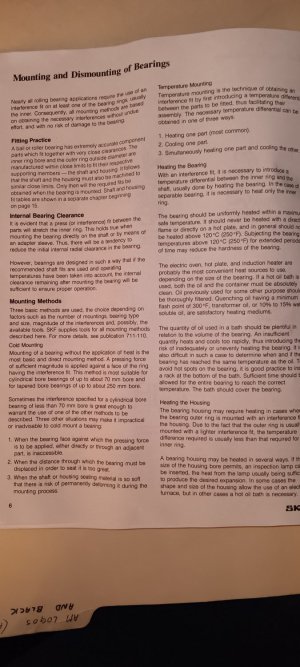

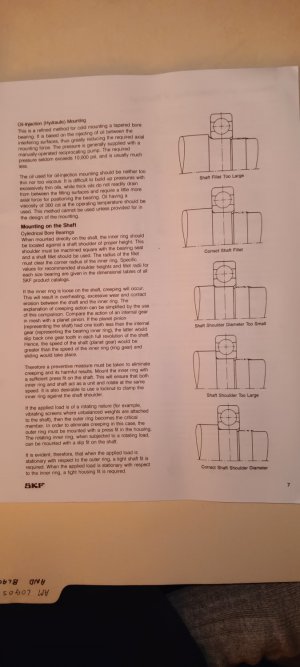

I don’t understand the comment about needing to bore out the quill, TRBs are typically wider than ACBs for the same ID, so you shouldn’t need to bore anything. Since tapered roller bearings are wider than angular contact bearings, you might need to make a spacer for the outer rings to use the ACBs. The spacer needs to be parallel to within 0.0001”, otherwise your tight tolerance bearings will perform like cheap industrial bearings. By changing to ACBs, you will be reducing the load capacity since TRBs can handle a larger load for the same size, and also will be more rigid. You can get precision TRBs, so unless you plan on running at higher speeds than a TRB can handle, I don’t see the reason to change.

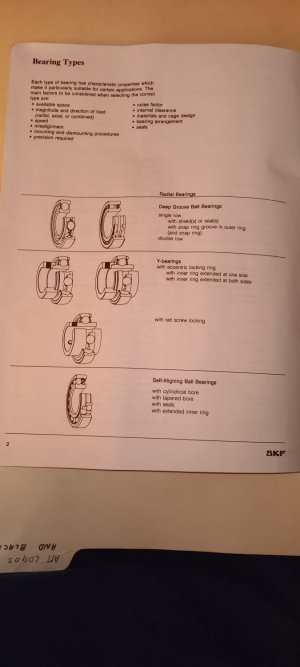

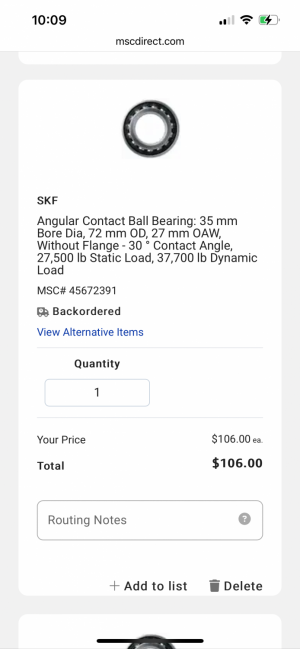

There are a number of varieties of angular contact bearings (ACB), with different contact angles, cage materials, tolerance classes, preload grinds, etc. Which ones to get will depend on how they will be used.

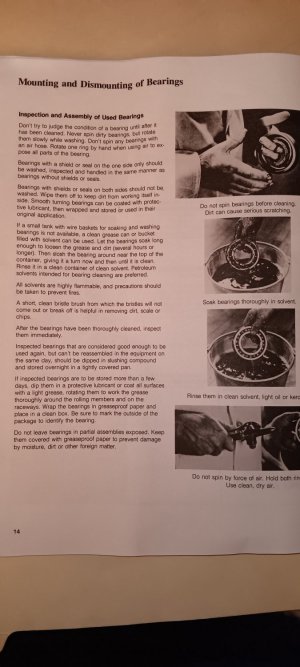

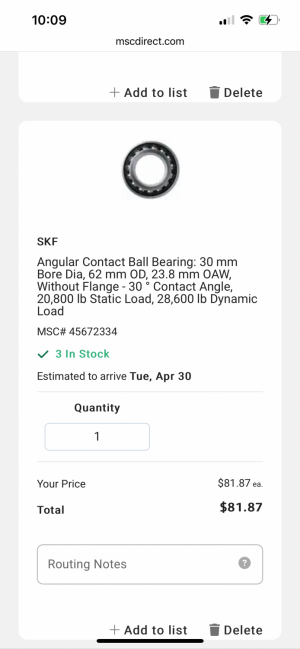

The $50 bearings are probably an industrial grade, the $150 might be a tighter tolerance bearing, but could also be a different variation that costs more such as a universal grind, can’t tell without the full part number. For spindle bearings, $400+ each would be a typical price in the smaller sizes and would be either P4, or ABEC 7 and a 15 degree contact angle. Which ones you need will depend on what is in there, and what will fit with the least modifications. What is the TRB full part number? It should be on the bearing, or you can measure it and get at least the ID and OD you will need for the ACB if you decide to go through with that change.

SKF, FAG, NSK, Timken are all interchangeable. All are quality bearings and you won’t see any difference in performance for identical bearings. Their part numbers will be different, so you will need to reference the bearing catalog for each manufacturer when selecting what you need.

There are a number of varieties of angular contact bearings (ACB), with different contact angles, cage materials, tolerance classes, preload grinds, etc. Which ones to get will depend on how they will be used.

The $50 bearings are probably an industrial grade, the $150 might be a tighter tolerance bearing, but could also be a different variation that costs more such as a universal grind, can’t tell without the full part number. For spindle bearings, $400+ each would be a typical price in the smaller sizes and would be either P4, or ABEC 7 and a 15 degree contact angle. Which ones you need will depend on what is in there, and what will fit with the least modifications. What is the TRB full part number? It should be on the bearing, or you can measure it and get at least the ID and OD you will need for the ACB if you decide to go through with that change.

SKF, FAG, NSK, Timken are all interchangeable. All are quality bearings and you won’t see any difference in performance for identical bearings. Their part numbers will be different, so you will need to reference the bearing catalog for each manufacturer when selecting what you need.

First of all, Thank you. Your knowledge is invaluable. This is exactly the kind of information I needed. I guess I just assumed that a higher precision bearing would yield higher precision as far as spindle runout goes. I’m certainly not opposed to going back to a taper bearing if that’s what would be ideal. I would like to put a better quality bearing in there while I’m here. The bearings that were in there were already discolored and starting to fail, I assume due to excessive preload. As far as the boring goes, it seems that what I was looking at was all wider than my taper bearings by a few millimeters. I will post up some numbers and pictures of what I have when I get home this evening, so that you can see what I’m working with. I am also not opposed to spending the money required to get some decent bearings in there.I don’t understand the comment about needing to bore out the quill, TRBs are typically wider than ACBs for the same ID, so you shouldn’t need to bore anything. Since tapered roller bearings are wider than angular contact bearings, you might need to make a spacer for the outer rings to use the ACBs. The spacer needs to be parallel to within 0.0001”, otherwise your tight tolerance bearings will perform like cheap industrial bearings. By changing to ACBs, you will be reducing the load capacity since TRBs can handle a larger load for the same size, and also will be more rigid. You can get precision TRBs, so unless you plan on running at higher speeds than a TRB can handle, I don’t see the reason to change.

There are a number of varieties of angular contact bearings (ACB), with different contact angles, cage materials, tolerance classes, preload grinds, etc. Which ones to get will depend on how they will be used.

The $50 bearings are probably an industrial grade, the $150 might be a tighter tolerance bearing, but could also be a different variation that costs more such as a universal grind, can’t tell without the full part number. For spindle bearings, $400+ each would be a typical price in the smaller sizes and would be either P4, or ABEC 7 and a 15 degree contact angle. Which ones you need will depend on what is in there, and what will fit with the least modifications. What is the TRB full part number? It should be on the bearing, or you can measure it and get at least the ID and OD you will need for the ACB if you decide to go through with that change.

SKF, FAG, NSK, Timken are all interchangeable. All are quality bearings and you won’t see any difference in performance for identical bearings. Their part numbers will be different, so you will need to reference the bearing catalog for each manufacturer when selecting what you need.

If you could please guide me in my decision , I would be forever grateful.

I will say, that I’m not planning on running any additional speed outside of what the machine will currently do. Again Thank you for all your help

- Joined

- Apr 10, 2021

- Messages

- 594

I would stay with a better quality tapered bearing than swap to an A/C in a lower end machine. There are lots of unknowns when going to an entirely different type of bearing, as mentioned above. you really need someone who knows the design on the machine, and spindle to recommend the appropriate conversion and the benefit vs cost isn't all that great on that machine. Dave