- Joined

- Nov 13, 2014

- Messages

- 41

I'm going to take a wild guess here, should I use a turning tool with a round insert that's 5/8" in diameter, or is there another way?

I'm going to take a wild guess here, should I use a turning tool with a round insert that's 5/8" in diameter, or is there another way?

www.hobby-machinist.com

www.hobby-machinist.com

It depends . . .

The title says 5/8" radius and the OP says 5/8" diameter. Please clarify.

What kind of lathe are you using? Is it stout enough to handle a large round insert/cutter?

A lot of cutting edge in the cut means a lot of cutting force and potential damage/chatter on the workpiece.

Is the desired feature on the face of the workpiece or on the OD? or ID?

The simple answer is to get a radius turning tool.

Suggested reading:

[How-To] - Ask a Better Question

Asking better questions will get you better replies. By asking a question, you're asking others to do some work for your benefit. Please put in the effort to ask a better question so the replies can be more focused, useful to your issue and show respect for the contributors. A good question...www.hobby-machinist.com

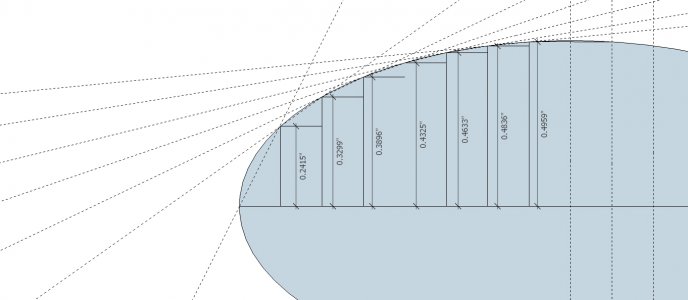

OKThe stock is stainless steel. It is a pulley for a capstan winch that will use 5/8" diameter rope. The inside corners need to be rounded as is tradition, so it is on the OD. The lathe is a PM 11 x 27 . It's not a super precision cut, but needs to be smooth when finished. If that has to be done later with emery cloth so be it.

The size and type of the pulley can make a big difference. A one inch od pulley and a six inch od is like night and day. Same as 303 stainless versus 316.I'm going to take a wild guess here, should I use a turning tool with a round insert that's 5/8" in diameter, or is there another way?