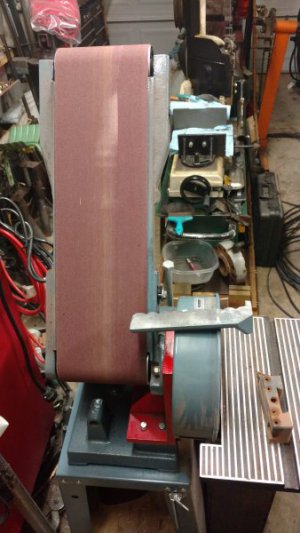

I have no idea of the correct place to post this repair of my ENCO 6 x 48" Belt Sander. When it arrived, nearly every part was dented & the main brace was broken into two parts. I was already aware that replacement parts from Grizzly can take 6 months. I really did not care to find out what hassle a warrantee claim with ENCO might be. The broken part, to my way of thinking is inferior. Instead, I made my own. The only tools needed were a band saw, rotary table & mill.