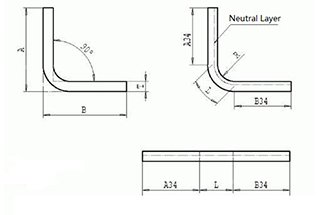

I've got a bunch of strips of 0.190 aluminum (5052), about 3-4 cm, wide, and I need to bend them to look like this:

I've got access to a brake that can be used on stuff up to 1/8", but I assume that limit is for really tight bends. As you can see, aside from that left-most 90-degree bend, these are all comparatively soft. Can I use a brake for this by moving the fingers back away from the edge (I apologize for not knowing all the words --- I'm a complete amateur) so that the resulting bend will be 'softer'? (In my case, it'd be OK if the first bend were a bit softer as well.)

By the way, the brake is pretty heavy duty -- not the kind of thing roofers use for flashing. It looks a lot like this one:

One a related note: suppose that the left-most "tab" had a 1/4" diameter hole drilled in it, pretty much dead center. If this is clamped under the "finger" on the brake, will the bend be affected at all? I'm assuming not, but whenever I assume something, it bites me in the butt, so I thought I'd ask -- my order-of-work depends on this.

Thanks in advance for any suggestions.

I've got access to a brake that can be used on stuff up to 1/8", but I assume that limit is for really tight bends. As you can see, aside from that left-most 90-degree bend, these are all comparatively soft. Can I use a brake for this by moving the fingers back away from the edge (I apologize for not knowing all the words --- I'm a complete amateur) so that the resulting bend will be 'softer'? (In my case, it'd be OK if the first bend were a bit softer as well.)

By the way, the brake is pretty heavy duty -- not the kind of thing roofers use for flashing. It looks a lot like this one:

One a related note: suppose that the left-most "tab" had a 1/4" diameter hole drilled in it, pretty much dead center. If this is clamped under the "finger" on the brake, will the bend be affected at all? I'm assuming not, but whenever I assume something, it bites me in the butt, so I thought I'd ask -- my order-of-work depends on this.

Thanks in advance for any suggestions.

Last edited: