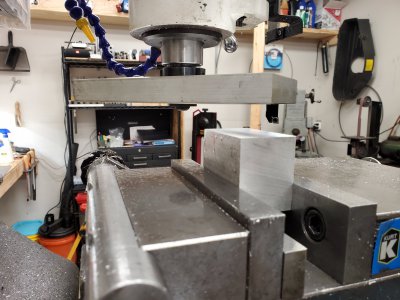

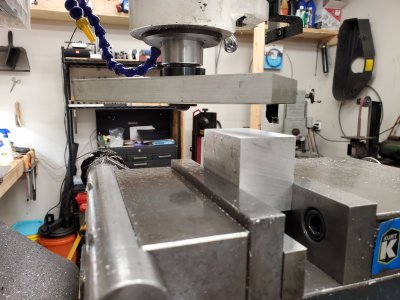

A while back I decided that I wanted a bigger fly cutter. Trueing up that head last night showed that the job doesn't require heavy cuts or high tool pressures. My goal is to cut just over 8", which is the width of my table.

This is what I came up with from the materials and tools on hand. I used a 1" x 4" aluminum plate 9" long, a 1.0625" shell mill arbor, and a 12mm Chinese boring bar.

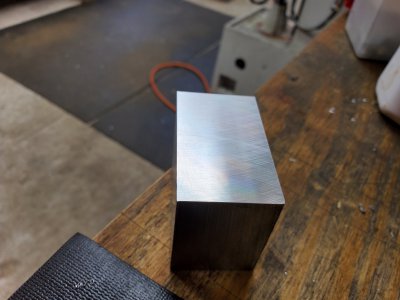

First, my boring facing head did me proud. I haven't spent much time practicing with it and it did very well. I hit 0.0001" over the arbor diameter but still couldn't get it started without heating the aluminum.

I fly cut the top, cut the length, and chamfered in the same set up off the same zero.

This is what it looks like.

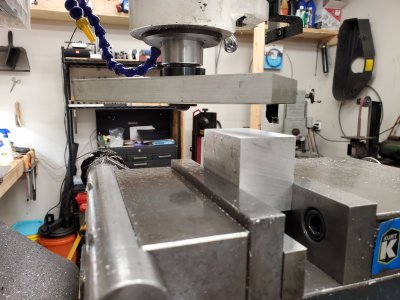

It's a flying wheel of death..... At 660 rpm it doesn't shake the machine at all. Much less than my standard fly cutter with a 1/2" tool bit.

I went to slow it to the fastest low gear speed and accidentally spun it up to 2720. No shaking. Just fear......lol.

I just finished it a bit ago and only took 2 test cuts. With a CCGT21.50.5 it looked like a mirror on the front edge of the pass. The light back drag caused a funky pattern. My mill is trammed so tight it lightly back drags both ways. I'm convinced I just need to orient the insert so its square to the cut and all will be fine. I'll fix that in the morning.

The funky-ness might be the interaction of the cross hatching.

I am definitely happy so far. Only one bug to work out. The balance isn't an issue so far.

This is what I came up with from the materials and tools on hand. I used a 1" x 4" aluminum plate 9" long, a 1.0625" shell mill arbor, and a 12mm Chinese boring bar.

First, my boring facing head did me proud. I haven't spent much time practicing with it and it did very well. I hit 0.0001" over the arbor diameter but still couldn't get it started without heating the aluminum.

I fly cut the top, cut the length, and chamfered in the same set up off the same zero.

This is what it looks like.

It's a flying wheel of death..... At 660 rpm it doesn't shake the machine at all. Much less than my standard fly cutter with a 1/2" tool bit.

I went to slow it to the fastest low gear speed and accidentally spun it up to 2720. No shaking. Just fear......lol.

I just finished it a bit ago and only took 2 test cuts. With a CCGT21.50.5 it looked like a mirror on the front edge of the pass. The light back drag caused a funky pattern. My mill is trammed so tight it lightly back drags both ways. I'm convinced I just need to orient the insert so its square to the cut and all will be fine. I'll fix that in the morning.

The funky-ness might be the interaction of the cross hatching.

I am definitely happy so far. Only one bug to work out. The balance isn't an issue so far.