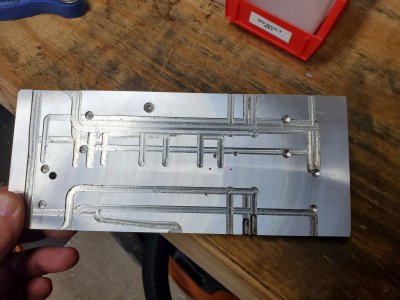

You are looking at a test part.Setting the cutting radius to just over the part width has lots of advantages, I suspect most have been detailed on this forum somewhere.

In your setup it looks like the part is about 2" wide, using the cutter with a 4" radius has the tool cutting for about 8% per revolution. It may be an idea to drill more holes for different cutting radii.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bigger fly cutter

- Thread starter Batmanacw

- Start date

- Joined

- Sep 2, 2013

- Messages

- 5,100

Yes, true of all rotating objects, but I think round would do a lot less damage. Probably why you don't see that shape in commercial use. Mike

That's pretty much the case for any fly cutter, isn't it?

Yes, true of all rotating objects, but I think round would do a lot less damage. Probably why you don't see that shape in commercial use. Mike

I'm the only one who will ever use it. Making it heavier was not my goal.

Every transition from pass to pass is an opportunity for leaks. It is preferred to have a consistent finish around each passage for the best possible seal.I'm intrigued why it is preferable to cut the whole face in one pass. As this is not a decorative face, would several overlapping passes with a smaller cutter still work as well?

I worked on the balance this morning. The weight of the boring bar and set screw was enough to put it out of balance a little. Drilling and reaming a hole for a 7" swing helped a bunch. It still needed a few holes from the opposite side to get on balance. I did the final balance by using longer set screws to get it as close as I can with a crude setup.

There is now no discernable wiggle in the machine. Smooth as glass.

There is now no discernable wiggle in the machine. Smooth as glass.