I see from your other post it looks like you are probably looking for a mill to support your RC / modelling hobby. I'm not that familiar with any of the mills you've listed but both vendors are pretty solid, I'm a regular customer of both for tools.

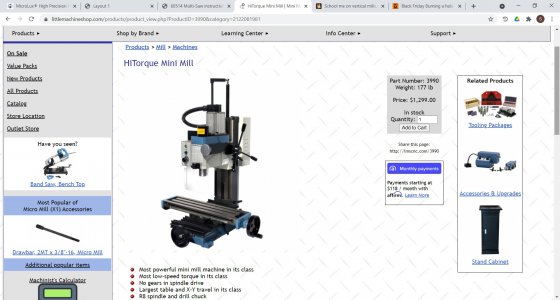

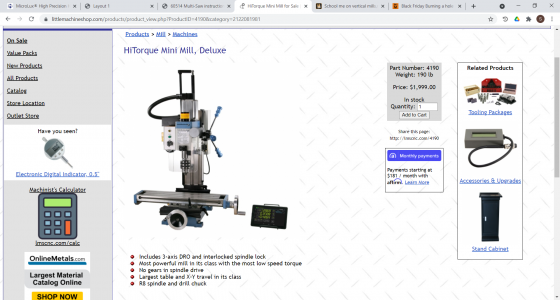

Of those you've listed I'd probably go with the LMS 3990 / 4190, as it is the biggest of the bunch and small mills run out of room quickly. It also is cheaper (3990) anyway than the Microlux. I'm not sure if the 4190 is really worth paying another $700, a 50% increase over the 3990. At almost $2000 I'd be seriously tempted to go a bit higher and get something bigger like a Precision Matthews PM25 ($2300) if you could manage the space.

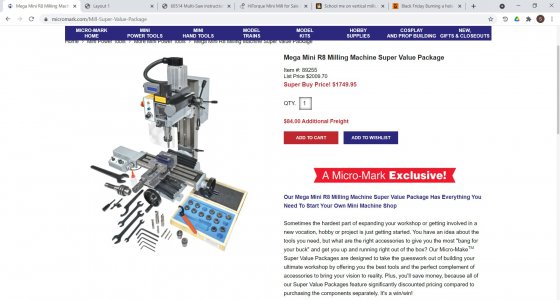

For the money the 4700 actually looks like a pretty decent little mill, but spending $300 for the extra 2" of table to spindle height on the 3990 is worthwhile in my opinion.

Other than rigidity the biggest issue you run into with small mills is the height between the spindle and the table. 9-1/2" on the 4700, 10" on the Microlux, and 11-1/2" on the 3990/4190. Off the top you lose at least 2" as soon as you factor in an end mill or drill bit, then add a vise, rotary table etc to the table and that space goes away quickly. As far as Rigidity at 175lbs the 3990 is quite a bit heavier than the others, the Microlux is 110lbs, so not much heavier than the 4700 at 106lbs.

I have a Sherline 5400 mill, which I also bought for making model parts. It does a fine job for the small parts I wanted to make. You mentioned it seeming too small, but with the extended column the 5400 actually has a 1/2" more distance spindle to table than the 3990. No doubt the 3990 is the winner in rigidity though since it weighs 3x as much. Not trying to sway you to Sherline, but I wouldn't dismiss Sherline or Taig for their seemingly small size, they have a much larger work envelope than their size would suggest and great support in regard to the options and tooling available.

On the other end I also have a small 6x24" Clausing knee mill. The Sherline is nice for small parts with its high RPM for small end mills, but the Clausing is what I go to for anything bigger than a couple of inches. The PM25, and Grizzly G0704 are of a similar size and power in a benchtop mill. Much smaller and easier to move than a Bridgeport, but a lot more capable than the mini-mills.

None of the machines you mentioned seem to actually be on sale for Black Friday so unless you just need to spend money you don't really have a time crunch to make a decision. A couple of things I would look at to help decide between mills is:

Max table to spindle height, this is a more important spec than Z axis (vertical) travel. You really never need to touch the spindle to the table so where 10" of travel may seem like an advantage over 8" on machines with 11-12" spindle to table height, the reality is you will rarely see an actual difference in use.

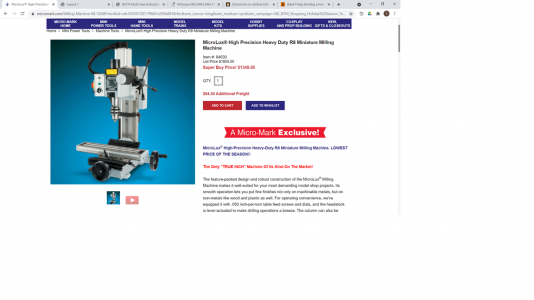

I'd also say Y axis (in and out) is a more critical comparison than the X axis (side to side) travel since the Y axis is often far more constrained, particularly on small mills. At only 4" the Microlux R8 has less Y axis travel than many smaller mills including Sherline. Of those you mentioned the 4700 actually has the most at 5.9". 5 to 5-1/2" of Y travel is pretty typical of small bench top mills.

X axis travel is not unimportant but unless you are looking at a lot of long projects or a mill has a significantly shorter X travel than others of a similar size, it is the axis you are least likely to exceed on the small projects suitable for a small mill.

Max RPM of the spindle, small drills and end mills need higher rpms. 2500-3000rpm is fairly typical of small mills, the 4700 goes up to 5000 rpm, Sherline and Taig have options allowing 10,000 rpm.

Compare this to a Dremel tool which is designed around 1/8" cutters. Dremels are capable of 50,000 rpm, so if you are thinking about 1/8" or smaller endmills even the fastest small mills are well below the optimum speeds for tiny end mills.

In your other post you mentioned debating between R8 vs MT vs ER spindles. Personally I don't think it really matters much on mills of this size. R8 is very common on larger mills, but on these small mills you are most likely just going to be using collets or an end mill holder. All of these are easy to find and of a similar price. You are looking at maybe $100 for a collet set so not a huge savings if you later upgrade to a full size mill and can transfer your collet set over.

On a bigger mill it can be more of an issue, since there is more spindle mounted tooling that you might want to use, and can be a particular issue on some older mills that use a less common or proprietary spindle taper.

Those are my thoughts anyway, and welcome.