- Joined

- Jun 26, 2013

- Messages

- 191

Hi All - I'm looking for a little advice on the proper procedure for boring on the lathe.

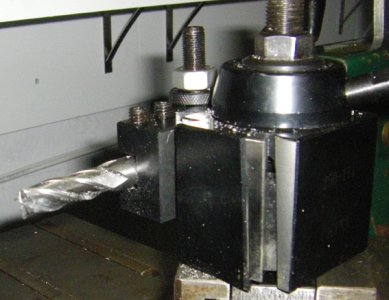

I have a piece of 2.5" dia round stock (2" long, steel) mounted in a 3-jaw chuck on my G0602 lathe. I need to bore a hole 1.5" in dia, 1" deep with a (relatively) flat bottom. I've center drilled, drilled in 1" with about a 1/4" bit, then with a 1/2" bit. I have a small set of boring bars, like these:

My question is probably pretty basic, but I haven't stumbled across the answer yet - I'm also finding it difficult to actually put the question into words...

Should I be working the hole larger by removing metal from the 'face' of the bar (out to 1.5" dia, then return to center, extend tool further into the hole and work 'out' again, repeat), or should I be enlarging the diameter of the existing hole all the way to the bottom of the hole (retract the tool, slightly increase diameter, plunge again, repeat)? I could see either approach working, just curious which would be the "right" way to do it.

Thanks!

I have a piece of 2.5" dia round stock (2" long, steel) mounted in a 3-jaw chuck on my G0602 lathe. I need to bore a hole 1.5" in dia, 1" deep with a (relatively) flat bottom. I've center drilled, drilled in 1" with about a 1/4" bit, then with a 1/2" bit. I have a small set of boring bars, like these:

My question is probably pretty basic, but I haven't stumbled across the answer yet - I'm also finding it difficult to actually put the question into words...

Should I be working the hole larger by removing metal from the 'face' of the bar (out to 1.5" dia, then return to center, extend tool further into the hole and work 'out' again, repeat), or should I be enlarging the diameter of the existing hole all the way to the bottom of the hole (retract the tool, slightly increase diameter, plunge again, repeat)? I could see either approach working, just curious which would be the "right" way to do it.

Thanks!