-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

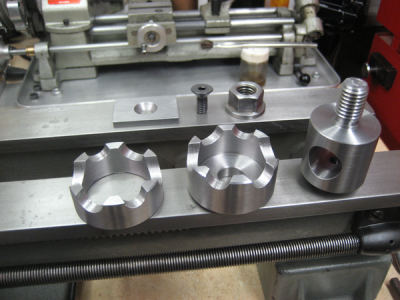

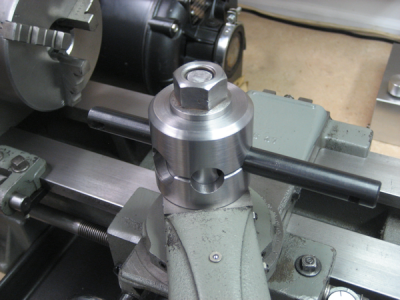

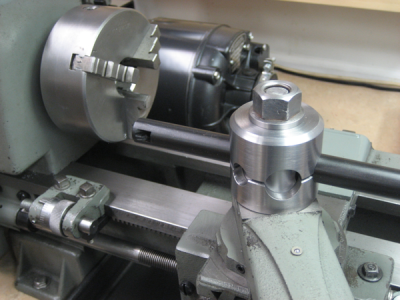

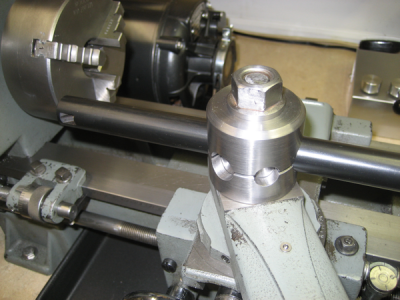

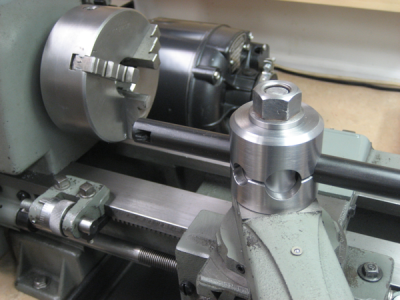

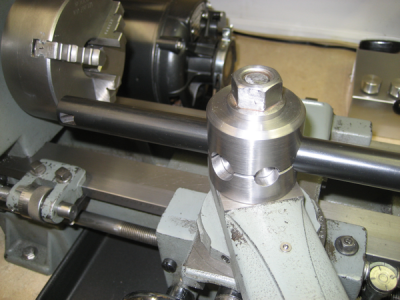

Boring bar holder

- Thread starter ksierens

- Start date

- Joined

- Sep 11, 2013

- Messages

- 115

Beautiful machining work there!

Is there any special reason why you have so many circular cutouts for a single boring bar tool holder?

Oh, never mind!...I just noticed that they are for different sizes of bars.

I do need my glasses! :lmao:

Is there any special reason why you have so many circular cutouts for a single boring bar tool holder?

Oh, never mind!...I just noticed that they are for different sizes of bars.

I do need my glasses! :lmao:

Last edited:

- Joined

- Dec 17, 2012

- Messages

- 630

Beautiful machining work there!

Is there any special reason why you have so many circular cutouts for a single boring bar tool holder?

They are different sizes for different boring bars.

- Joined

- Dec 30, 2011

- Messages

- 81

I take it you bought the bars already made?

Yes, I picked them up from KBC tool. No broaches or arbor press, and at their prices, no reason to make them anyways.

Nice work, i must make one of these. i made an adapter a while ago to do away with the top slide ( it can be in the way at times) the 4 way tool post is mounted on top, i can then mount this tool and have a good rigid set up,:allgood: