I should have written this up previously, but you can see the sequence of construction in the POTD thread:

http://www.hobby-machinist.com/show...&highlight=boyar+schultz+dust+hood#post175324

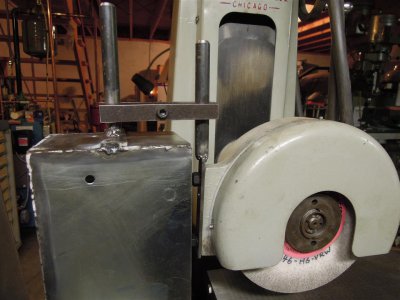

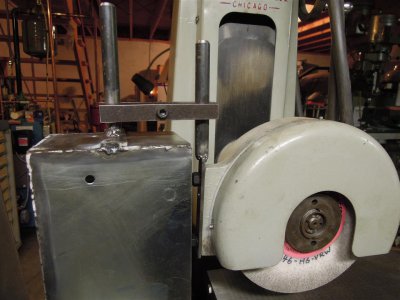

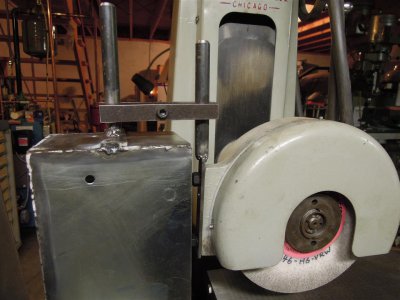

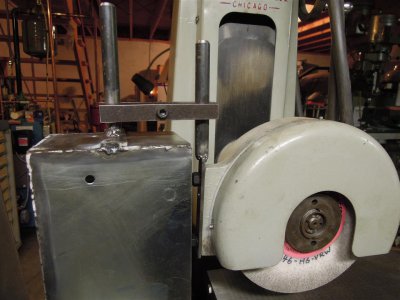

Having used it now for a short while, I learned that it's allowing about 10% of the dust to escape below the level of the dust hood. Obviously it needed to be lower, but when it's attached to the wheel guard, it would strike the lower edge of the magnetic chuck. I can see now why some Boyar Schultz surface grinders have a big fixed funnel shaped dust collector at the end of the table, where the left shield would be. Since I had a fair amount of time in building the current dust hood, I wanted to modify it rather than making something new. I could see two options. One, I could set it on a stand at the end of the magnetic chuck and come up with some way to move it from side to side to match where on the chuck the piece was being ground. I'd be out of luck if the item to be ground was taller than the dust hood. Option two was to hinge it so that it would swing up when end of the magnetic chuck hit it. I clamped a hinge to it to prototype it and it seemed to work. I'll make the new pieces and weld them to the hood tomorrow.

http://www.hobby-machinist.com/show...&highlight=boyar+schultz+dust+hood#post175324

Having used it now for a short while, I learned that it's allowing about 10% of the dust to escape below the level of the dust hood. Obviously it needed to be lower, but when it's attached to the wheel guard, it would strike the lower edge of the magnetic chuck. I can see now why some Boyar Schultz surface grinders have a big fixed funnel shaped dust collector at the end of the table, where the left shield would be. Since I had a fair amount of time in building the current dust hood, I wanted to modify it rather than making something new. I could see two options. One, I could set it on a stand at the end of the magnetic chuck and come up with some way to move it from side to side to match where on the chuck the piece was being ground. I'd be out of luck if the item to be ground was taller than the dust hood. Option two was to hinge it so that it would swing up when end of the magnetic chuck hit it. I clamped a hinge to it to prototype it and it seemed to work. I'll make the new pieces and weld them to the hood tomorrow.