- Joined

- Feb 25, 2021

- Messages

- 3,129

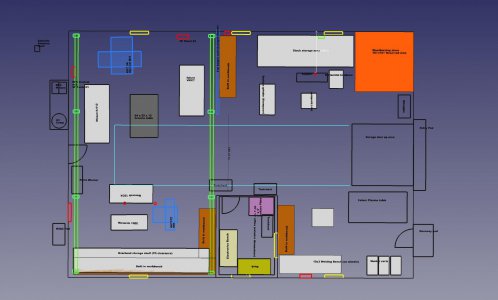

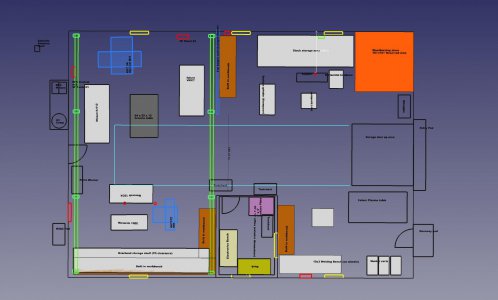

I mentioned this in my thread on building a new shop, but I thought I'd start a new thread on this. Shop was finished up early fall of last year. I built the shop with the intention of putting in a bridge crane. In this picture of the shop layout, the bridge crane rails are shown in green on the right half of the shop.

I put in the 8 steel support posts for the crane as the last part of finishing out the shop construction, but held off on the bridge crane for financial reasons. Just picked up the steel to start building the rest of the crane. I had debated a bit on capacity. The side rails are supported by 4 posts each, which works out to be about a 13' span between posts, so it is fairly easy to size beams for capacity there. But the 24' bridge beam is, well a 24' span (actually about 23'). Of course there is no reason that those beams need to be the same size, and they aren't.

I'm not a licensed PE, so I'm not going to go into details on load calculations and beam sizes. I have done the load calculations so I am comfortable with my design but for safety/liability reasons I don't want to get into anything that sounds like I'm giving a detailed how-to on designing a crane. It is my hobby shop, OSHA approved design not required. I understand that probably implies some liabilty exposure. What doesn't these days?! I'll just say I used L/600 as my deflection goal as that is a standard that I found for bridge crane design. I compared that to a 5x safety factor. With those in mind, my crane will have a 2 ton capacity. I had originally considered 1 ton, but the incremental cost is not huge, and 2 ton allows me to hoist my smaller mill and two smaller lathes, which a 1 ton would not. Most of my use will be for 50-500lb items, chucks, rotary tables, or machine dissassembly. For lifting the big lathe, or big mill, I'd need 5 ton capacity, which would mean a motor driven bridge in addition to the cost of larger beams.

This week I picked up steel. Of course, getting 40' beams through a 10' door is not straightforward. Nor is hauling 40' beams. But, that part is done.

![IMG_4979[1].JPG IMG_4979[1].JPG](https://www.hobby-machinist.com/data/attachments/396/396342-d753507d9573f9ec835179f4a8da26f2.jpg)

It'll be a few weeks before I have another update, I tend to plod along on these projects.

I put in the 8 steel support posts for the crane as the last part of finishing out the shop construction, but held off on the bridge crane for financial reasons. Just picked up the steel to start building the rest of the crane. I had debated a bit on capacity. The side rails are supported by 4 posts each, which works out to be about a 13' span between posts, so it is fairly easy to size beams for capacity there. But the 24' bridge beam is, well a 24' span (actually about 23'). Of course there is no reason that those beams need to be the same size, and they aren't.

I'm not a licensed PE, so I'm not going to go into details on load calculations and beam sizes. I have done the load calculations so I am comfortable with my design but for safety/liability reasons I don't want to get into anything that sounds like I'm giving a detailed how-to on designing a crane. It is my hobby shop, OSHA approved design not required. I understand that probably implies some liabilty exposure. What doesn't these days?! I'll just say I used L/600 as my deflection goal as that is a standard that I found for bridge crane design. I compared that to a 5x safety factor. With those in mind, my crane will have a 2 ton capacity. I had originally considered 1 ton, but the incremental cost is not huge, and 2 ton allows me to hoist my smaller mill and two smaller lathes, which a 1 ton would not. Most of my use will be for 50-500lb items, chucks, rotary tables, or machine dissassembly. For lifting the big lathe, or big mill, I'd need 5 ton capacity, which would mean a motor driven bridge in addition to the cost of larger beams.

This week I picked up steel. Of course, getting 40' beams through a 10' door is not straightforward. Nor is hauling 40' beams. But, that part is done.

![IMG_4979[1].JPG IMG_4979[1].JPG](https://www.hobby-machinist.com/data/attachments/396/396342-d753507d9573f9ec835179f4a8da26f2.jpg)

It'll be a few weeks before I have another update, I tend to plod along on these projects.

Last edited: