I received my mobil lubricants today i ordered for my mill now i am looking for a resource for what oil goes where. I received 3 oils and a tube of lubriplate white grease. I dont want to use the wrong stuff in wrong places. I will continue doing my research but figured some of you may know offhand a good resource for the mobil oils application.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bridgeport lubrication questions.

- Thread starter Jseth

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

I don’t have a Bridgeport, but I put Mobil DTE in the headstock gearbox on my 16” swing lathe.

I use Mobil Vactra #2 on the ways (lathe), table (mill) & in the ball oilers on all of my machines.

I use Mobil Vactra #2 on the ways (lathe), table (mill) & in the ball oilers on all of my machines.

- Joined

- Sep 8, 2019

- Messages

- 4,392

From:

“16 ounces of: Mobile Velocite #10 spindle lubricant. This will be used in the spindle quill bearings on the 2J and 2J2 mills.

16 ounces of: Mobil DTE Heavy/Medium (ISO 68), which will be used to lubricate the spindle downfeed, drawbar spines, pulley cam, and spindle bearings (on the J and M head).

16 ounces of: Mobil Vactra #2 Way Oil, which will be used to lubricate the sliding Way surfaces of the mill, (The X, Y, and Z ways, and axis screws.

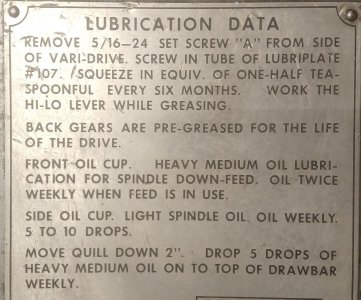

A tube of Lubriplate B105 grease (1 3/4 OZ) for the bull gear shift mechanism. This should get about a half a teaspoon squirt of grease every six months. I would guess this tube should last 2 or 3 years. The “B” in the B105 is Lubriplate’s designation for the formulation for the Bridgeport. The story (as told by Lubriplate), is that Bridgeport printed Lubriplate 107 on the lubrication plate on the side of the machines, and decided to let the mistake go. If you call Lubriplate looking for 107, this is what they will recommend. I’ve gotten this story from two different souces in the business, and thats good enough for me.”

“16 ounces of: Mobile Velocite #10 spindle lubricant. This will be used in the spindle quill bearings on the 2J and 2J2 mills.

16 ounces of: Mobil DTE Heavy/Medium (ISO 68), which will be used to lubricate the spindle downfeed, drawbar spines, pulley cam, and spindle bearings (on the J and M head).

16 ounces of: Mobil Vactra #2 Way Oil, which will be used to lubricate the sliding Way surfaces of the mill, (The X, Y, and Z ways, and axis screws.

A tube of Lubriplate B105 grease (1 3/4 OZ) for the bull gear shift mechanism. This should get about a half a teaspoon squirt of grease every six months. I would guess this tube should last 2 or 3 years. The “B” in the B105 is Lubriplate’s designation for the formulation for the Bridgeport. The story (as told by Lubriplate), is that Bridgeport printed Lubriplate 107 on the lubrication plate on the side of the machines, and decided to let the mistake go. If you call Lubriplate looking for 107, this is what they will recommend. I’ve gotten this story from two different souces in the business, and thats good enough for me.”

Perfect thank you erik!From:

“16 ounces of: Mobile Velocite #10 spindle lubricant. This will be used in the spindle quill bearings on the 2J and 2J2 mills.

16 ounces of: Mobil DTE Heavy/Medium (ISO 68), which will be used to lubricate the spindle downfeed, drawbar spines, pulley cam, and spindle bearings (on the J and M head).

16 ounces of: Mobil Vactra #2 Way Oil, which will be used to lubricate the sliding Way surfaces of the mill, (The X, Y, and Z ways, and axis screws.

A tube of Lubriplate B105 grease (1 3/4 OZ) for the bull gear shift mechanism. This should get about a half a teaspoon squirt of grease every six months. I would guess this tube should last 2 or 3 years. The “B” in the B105 is Lubriplate’s designation for the formulation for the Bridgeport. The story (as told by Lubriplate), is that Bridgeport printed Lubriplate 107 on the lubrication plate on the side of the machines, and decided to let the mistake go. If you call Lubriplate looking for 107, this is what they will recommend. I’ve gotten this story from two different souces in the business, and thats good enough for me.”

- Joined

- Apr 23, 2018

- Messages

- 6,533

Interesting, why do they spec both ISO 68 and Vactra #2? I thought they were nearly equivalent.

- Joined

- Aug 14, 2020

- Messages

- 60

I'm no expert, but the ISO68 number is just the viscosity. Yes, Vactra #2 has that same viscosity, but also has other components specifically tailored to the way lube application. I believe it's stickier than the DTE oil and there may be other differences as well.Interesting, why do they spec both ISO 68 and Vactra #2? I thought they were nearly equivalent.

- Joined

- Nov 14, 2020

- Messages

- 1,739

It's called a tactifier. I buy dollar store bar and chain oil and use it 50/50 with dollar store sae 30 oil. two dollars makes half a gallon.I'm no expert, but the ISO68 number is just the viscosity. Yes, Vactra #2 has that same viscosity, but also has other components specifically tailored to the way lube application. I believe it's stickier than the DTE oil and there may be other differences as well.