-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bridgeport Resto

- Thread starter N8TheGreat

- Start date

- Joined

- Oct 16, 2015

- Messages

- 38

lol unfortunately I don't ... yet

Looks like a stack a washer will have to do

Looks like a stack a washer will have to do

- Joined

- Oct 16, 2015

- Messages

- 38

- Joined

- Oct 16, 2015

- Messages

- 38

- Joined

- Oct 16, 2015

- Messages

- 38

- Joined

- Oct 16, 2015

- Messages

- 38

I must say I am liking it so far, runs great! very smooth and noise or vibrations whatsoever and everything works like the power feed

Drive still needs to be dialed in still like ramp up and down times and etc... but they will come in time.

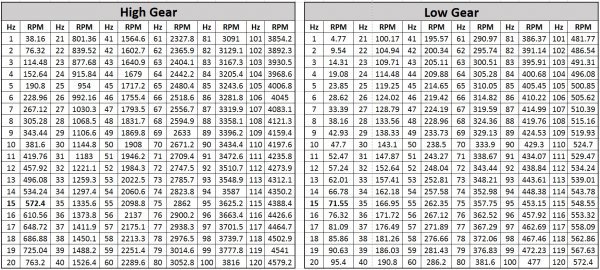

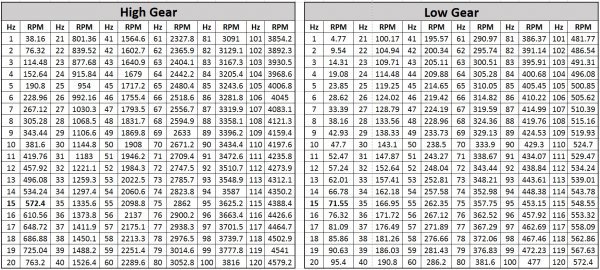

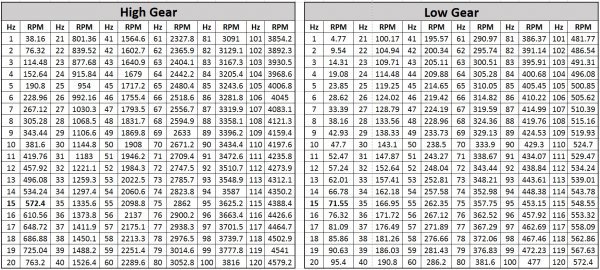

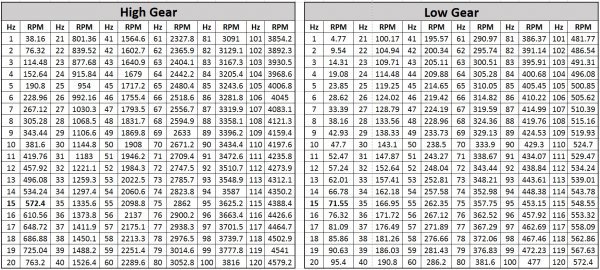

Also I very happy with the 2-pole motor choice with the pulley configuration and the High/Low gearing on the mill I have a huge RPM range to work with even at motors full torque.

I have a RPM chart I could share if anyone is curious or would like to do something similar.

Drive still needs to be dialed in still like ramp up and down times and etc... but they will come in time.

Also I very happy with the 2-pole motor choice with the pulley configuration and the High/Low gearing on the mill I have a huge RPM range to work with even at motors full torque.

I have a RPM chart I could share if anyone is curious or would like to do something similar.

- Joined

- Feb 8, 2014

- Messages

- 11,144

Nice job! I would be interested in learning more about how you did the spindle speed sensor. Would you post the details? I'm most interested in where and how you located the pickup and what it is actually ''seeing''.

- Joined

- Oct 16, 2015

- Messages

- 38

Here is my RPM chart, because I dont have what you may call a fancy motor($$$) I will only have full torque to around 15hz which is perfectly fine for me with my pulley's and gearing gets me down to around 70RPM at full torque I could always go slower to get the RPMs even lower as shown on the table.

- Joined

- Oct 16, 2015

- Messages

- 38

Nice job! I would be interested in learning more about how you did the spindle speed sensor. Would you post the details? I'm most interested in where and how you located the pickup and what it is actually ''seeing''.

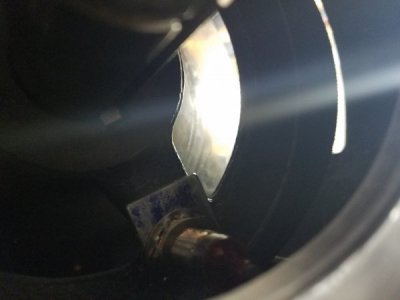

As for the sensor, its a hall sensor and I located the magnet on the pulley mounted to the spindle that way it is picking up the RPM of the spindle not the motor

I wish I would have gotten better pictures but you can just barely see the sensor here.

Because there is a 8:1 reduction in the High to Low gear selector on the mill I am working on a logic board that will do the division and then display to correct RPM at the tool when the machine is in low gear. so for now the RPM meter is only really relevant when in high gear but I am working on that. but that's another project

Last edited: