- Joined

- Feb 19, 2014

- Messages

- 112

Thank you everyone for the input and advice.

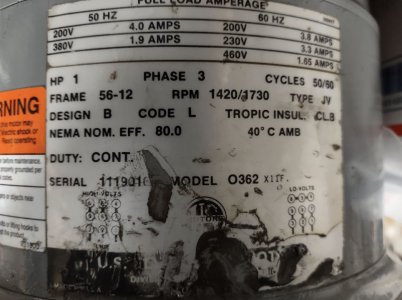

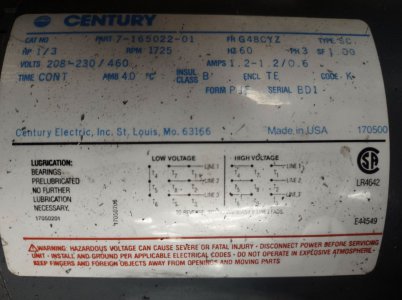

I’ll attach pictures of the mill with the power feed and the motor plaques

thats good to know I’ll keep that in mind. I am sure it’s a 3 phase motor. It’s actually a really old looking power feed with an actual motor hanging off the back of it...I’ll see if I can post a pictureTeco are decent VFD's for the mill, in particular for simple setups. As rabler indicated there is no practical way to run two dissimilar motors at different speeds simultaneously. Some VFD's have provisions for setting up/switching between two motors, but it is complicated to implement. Many of the Bridgeport drives were single phase input with DC motors, so I would check if it is truly a 3 phase drive motor. Option B, you could get another VFD for the drive, but the operation/speed control would need to be from the VFD and not the drive controls.

Given the cost of replacement of some of the Bridgeport motors, I would run the stock motor a bit more conservatively, like 30-90 Hz and a lower carrier frequency. You loose Hp and the mechanical advantage below the motor base speed, so one could overheat the motor is drilling a large hole over time.

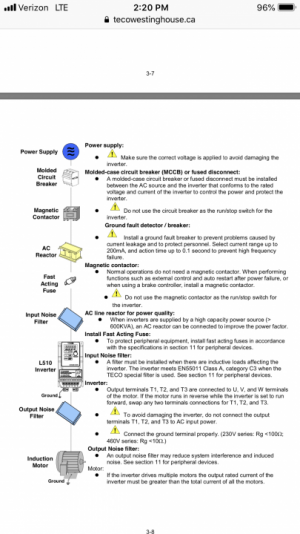

Yeah sounds like we have the same setup. I’ll probably just grab a cheaper simpler vfd for the power feed then.Sounds like you have the same setup I do. I do limit the speed range of the older main drive motor, for the reasons @mksj mentions. I think mine is slightly wider range, 20-100 I think. Any switches and other control electronics need to be removed from the circuit. The motor must connect directly to the VFD. You can use the FWD/REV switch if you like, but it needs to be rewired to the VFD input terminals. I used a simple 2-gang junction box from the local home store to make a simple control panel.

If the X power feed is the old gearbox style like mine, it has an older 3 phase motor dedicated to it. You need 2 VFDs in this case. I run the power feed at 60Hz and use the gears for speed control. There are times it would be nice to have it more variable with a simple knob like the main motor, but it gets the job done.

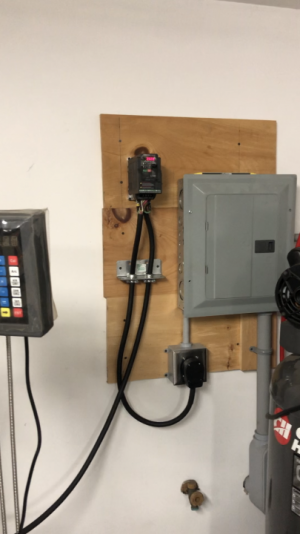

Teco makes nice devices, as do many others. They are more expensive, but often are more efficient etc.. That said, I went with cheap import VFDs and have been happy with them. You need to keep them away from chips and grinding dust, but that's easy enough. For the mill, mine are mounted to the wall behind the machine and high enough that chips are unlikely to get up there. I'm running 3 of them now, one on a belt grinder, and they work great.

Hey thank you! i wish it was 110. It’s definitely 3 phaseHey Threadkiller, congrats on the acquisition! I just recently went through this setup for a 1HP series 1 J Head BP with step pulleys. Running a 2.2Kw VFD to convert 1ph220 to 3ph380, I set my VFD to 60hz and do my speed adjustments via the belt and motor reversing via the Hi/Lo switch. This ensures the motor gets adequate cooling by running at the intended rpm.

For the power feed, double check the wiring as mine was only 110 and got its power by tapping one leg and ground from the 3ph. I now run 110 to a box on the body to split out for the lighting, dro, and power feed, then 220 dedicated to the VFD which goes directly to the reversing switch on the motor.

I’ll attach pictures of the mill with the power feed and the motor plaques