- Joined

- Dec 18, 2019

- Messages

- 6,447

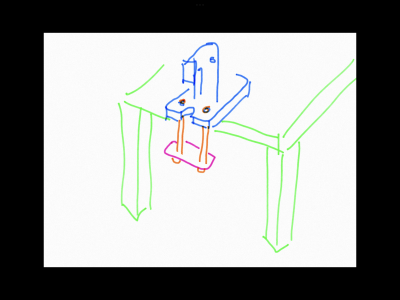

Good idea. This would require some interesting design to pull off. Obviously need to additionally bolt the arbor table to the floor in the front to prevent lifting. Probably have to bolt the front of the press to the table as well. If I put some steel plate under the arbor press and used it as the anvil I'd get enough clearance. I'd need something like a piece of 9 x 18 x 3/4 plate if a single piece.Not that you need it but I think one one of the common ways to get a bit more capacity (height) out of an arbor press is to just suspend a small secondary table beneath the existing foot of the press. Kind of like a stirrup if you need to visualize something. The press itself isn’t modified, just the relative position of the support for the work.

-frank