- Joined

- Apr 23, 2018

- Messages

- 6,532

A quick count looks like 26:13. The page @middle.road posted shows they are available unhardened. You can figure out how to fab up some adapters to mate the parts to the existing drive, I have confidence!

OK, I wanna know what voodoo you used to count them. I tried (3) times and couldn't... -heheA quick count looks like 26:13. The page @middle.road posted shows they are available unhardened. You can figure out how to fab up some adapters to mate the parts to the existing drive, I have confidence!

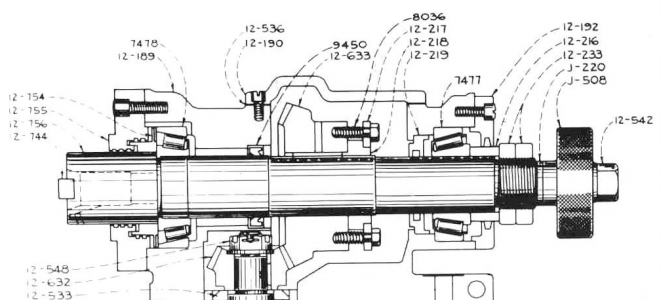

Nice Cal. Now that is some awesome invaluable information!Here's a section of the drawing for the cutter-head of the type used on your machine (several other versions were used on No. 12 millers):

The part that controls the axial position of the ring gear is an internally threaded ring, part number 12-218. You want to put witness marks on it and the spindle (12-756). Make the mark on the ring at keyway and you don't need to mark the spindle. You also want to count the number of exposed threads on the spindle behind the ring and measure the gap between the front of the ring gear and the front of the casting, so that you can get the threaded ring to approximately the right spot before lining up your witness mark. However, since your ring gear is trashed, you probably won't need to put it back in position, so you could skip marking it if you like.

The ring gear has 45 teeth with an OD of 4-1/2" and an ID of 1-9/16". The pinion has 21 teeth with and OD of 2-17/64" and an ID of 7/8".

I reached out to one of my contacts, the owner of American Machine & Gear Works. He looked at your photos an doesn't think the gears can be repaired. He can make new gears, but they'll be expensive.