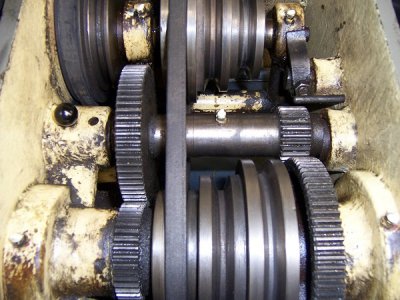

I have a bronze bushing on my spindle cone pulley that was used to fix the end of the cone pulley that had worn on the inside diameter. The bushing is a tight fit inside the cone pulley that spins freely around the diameter of the lathe spindle. The bushing spins around the lathe spindle when the backgear is engaged.

While looking for bolts for something totally unrelated, I came across the term "galvanic corrosion" (dissimilar metals corrosion), and found that bronze is not compatible with steel, and may cause the steel to corrode as long as there is the presence of an electrolyte (not a science mind here so not sure exactly how it all works).

Then I got to thinking how can bronze cause steel to corrode when the combination is used in many applications, even lathe bearings or bushing in the older lathes.

Then I got to thinking further that if it is an issue, then a good oil should prevent the corrosion. I was thinking a way oil equivalent to Vactra 2 would be good. The application is low speed. In back gear, it would turn no faster than 1000 rpm, much higher than I would use in backgear. The way oil would form a moisture barrier also.

Now for the questions:

1. Is galvanic corrosion (dissimilar metals corrosion) any concern in this application?

2. Is way oil good to use if there is any issue of corrosion, or in any event, in this application?

While looking for bolts for something totally unrelated, I came across the term "galvanic corrosion" (dissimilar metals corrosion), and found that bronze is not compatible with steel, and may cause the steel to corrode as long as there is the presence of an electrolyte (not a science mind here so not sure exactly how it all works).

Then I got to thinking how can bronze cause steel to corrode when the combination is used in many applications, even lathe bearings or bushing in the older lathes.

Then I got to thinking further that if it is an issue, then a good oil should prevent the corrosion. I was thinking a way oil equivalent to Vactra 2 would be good. The application is low speed. In back gear, it would turn no faster than 1000 rpm, much higher than I would use in backgear. The way oil would form a moisture barrier also.

Now for the questions:

1. Is galvanic corrosion (dissimilar metals corrosion) any concern in this application?

2. Is way oil good to use if there is any issue of corrosion, or in any event, in this application?