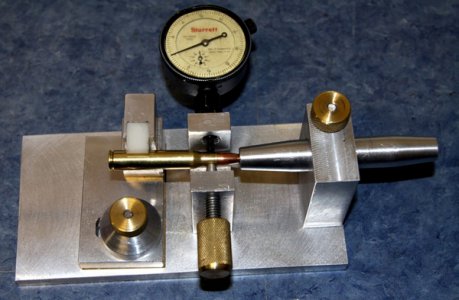

Ron Hoen, Lester Bruno and Fred Sinclair have sold these types of devices in the past. There are some other manufacturers as well. don't know if Sinclair still has them but I believe Lester does. I have one of Lester's that I keep in my Benchrest box. It has a .0005 indicator on it. We use them to verify the seating die and sizing die performance. In the Bench game, we do everything we can to make things consistent. With the bullets, powder, barrels, actions, stocks and triggers available today, 5 shot groups are regularly shot smaller than .2". Teen aggregates (5 targets, each with 5 shots that average .199 or less) happen at matches on a regular basis. I will not demean the 30-06 100 yard .750 groups. That is a fine group for a hunting rifle. I have an old Remington 700 in 30-06 that will allow me to get 3 (130 grain) bullets to sometimes touch at 200 yards. One of those little rounds went all the way thru a mule deer at 257 yards a couple years ago. That is fantastic for a hunting rifle. An inch or two makes very little difference to a deer. With load tuning, careful selection of bullets, powder and brass, we can easily make a gun go from 5 inch groups to 1 or two inch groups. If we are lucky to get a decent barrel from the manufacturer, those groups may shrink to the .75 or so as the original poster stated. In my experience that is about as good as it gets. The guns are built to SAMMI specs i.e., loose. To get the most out of a rifle, you need to have a close fit between the cartridge and the chamber. The bullet seating should allow the bullet to just touch the rifling or be just a few thousands off. Case necks are turned to the "tenth" to insure that each bullet is "gripped" with the same tension. etc, etc, etc. The list goes on. We go to great lengths to get that last quarter inch out of the group. Then we go to greater lengths to get the last hundred thou out of the group. Then we spend even more on things like bullet straighteners that at least make us think that they help reduce our group size. Do they? Don't know but I do know that they won't help much if at all on a hunting rifle. But if they make you more confident that you have the best ammo available, then they indeed have some value. Just my view of things.

Earl