- Joined

- Feb 2, 2013

- Messages

- 3,628

I get to play with some pretty cool equipment sometimes, today was one of those days...

i had a Busch 063-132 Rotary Vacuum Pump - 2.2kw (3hp) ,come across the bench this morning.

the operator/owner claimed high noise and loss of vacuum-which, really sucks for him! (sorry, i couldn't resist)

looks like i'll be able to salvage this one.

i'll need to replace the sleeve bearings , the seals and vanes to bring it back to right again.

here's the exploded view for those who have not seen the innert's of a vacuum pump before.

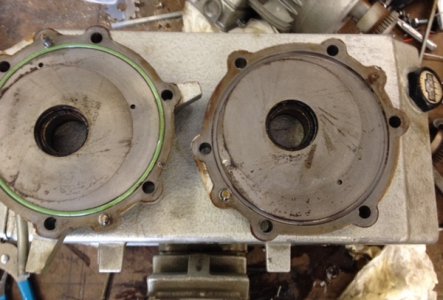

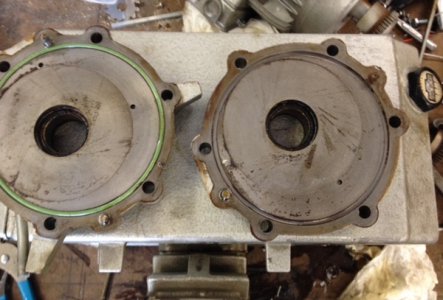

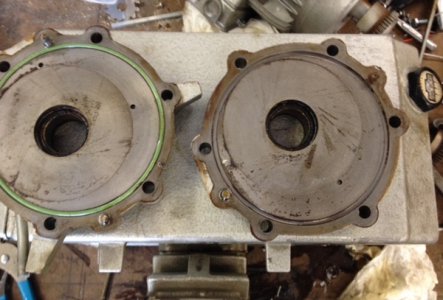

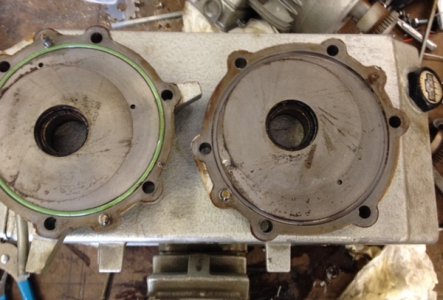

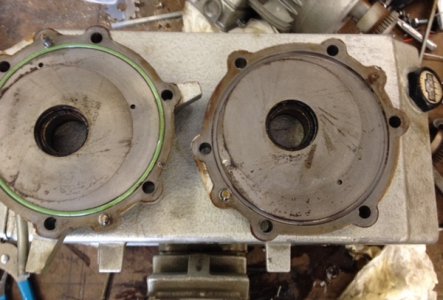

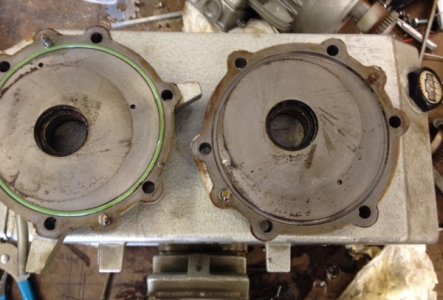

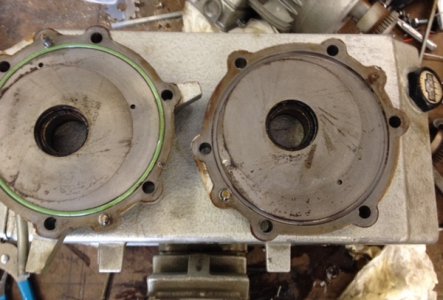

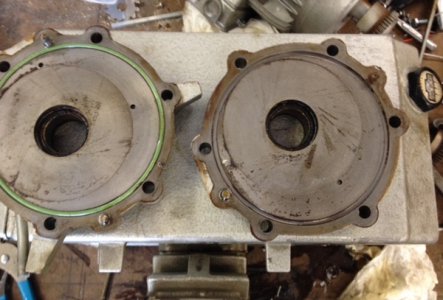

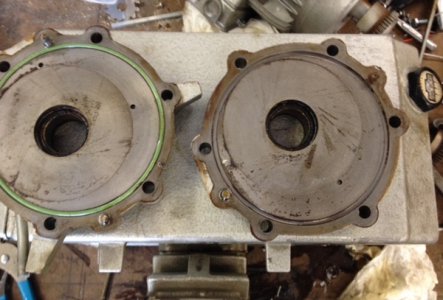

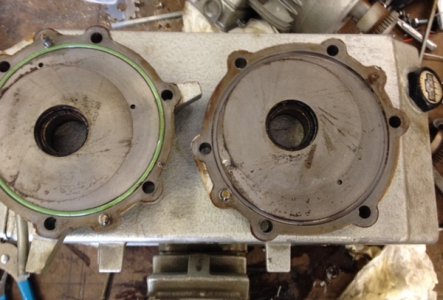

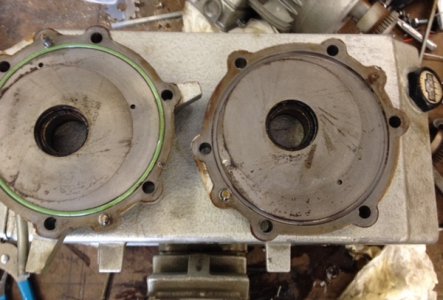

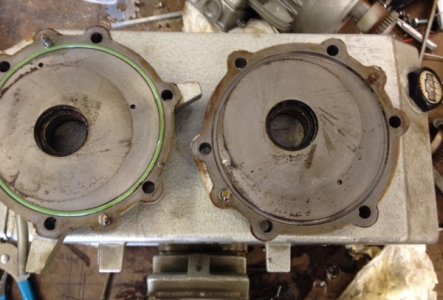

the vacuum pump sealed end caps, below.

a view of the rotor and barrel assemblies

a picture of one of the vanes, slid out for viewing.

heres a pic of badly worn bearing race and it's corresponding worn bearing shell

and the other worn bearing race and bearing shell

in the next episode...

i'll be further breaking the pump down and replacing the worn parts.

thanks for looking,

i'm always happy to answer questions and hear comments.

i had a Busch 063-132 Rotary Vacuum Pump - 2.2kw (3hp) ,come across the bench this morning.

the operator/owner claimed high noise and loss of vacuum-which, really sucks for him! (sorry, i couldn't resist)

looks like i'll be able to salvage this one.

i'll need to replace the sleeve bearings , the seals and vanes to bring it back to right again.

here's the exploded view for those who have not seen the innert's of a vacuum pump before.

the vacuum pump sealed end caps, below.

a view of the rotor and barrel assemblies

a picture of one of the vanes, slid out for viewing.

heres a pic of badly worn bearing race and it's corresponding worn bearing shell

and the other worn bearing race and bearing shell

in the next episode...

i'll be further breaking the pump down and replacing the worn parts.

thanks for looking,

i'm always happy to answer questions and hear comments.

. Loooookin gooooood…Dave.

. Loooookin gooooood…Dave.