- Joined

- Mar 6, 2024

- Messages

- 8

Hey guys,

Im new to this group and new to cam lock spindles in general. I recently got a Central machinery 12x36 lathe. It was made in 1998 and is in pretty good condition.

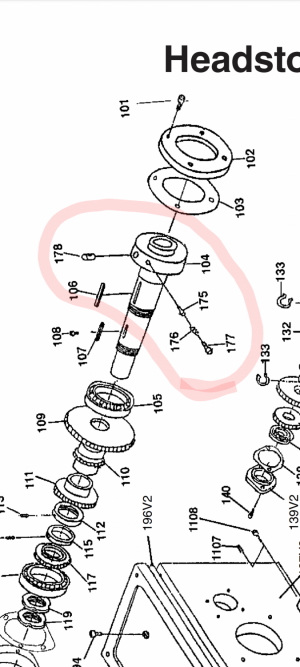

It however did not come with the chuck or the cam lock hardware in the spindle. According to the manual it a D1-4 cam lock type.

I bought a new 6'' 3 jaw chuck from Grizzly with D1-4 cam locks in it. I got the locking cams that go into the spindle from MSC.

The problem is when i put the chuck on the cams on the spindle just turn freely and wont lock down in the lathe cam studs.

Ive adjusted the studs in the chuck from all the way threaded in to out as far as they can go and still get the locking alen in.

Not sure what else to try.Thanks in advance for in info yall can provide.

Im new to this group and new to cam lock spindles in general. I recently got a Central machinery 12x36 lathe. It was made in 1998 and is in pretty good condition.

It however did not come with the chuck or the cam lock hardware in the spindle. According to the manual it a D1-4 cam lock type.

I bought a new 6'' 3 jaw chuck from Grizzly with D1-4 cam locks in it. I got the locking cams that go into the spindle from MSC.

The problem is when i put the chuck on the cams on the spindle just turn freely and wont lock down in the lathe cam studs.

Ive adjusted the studs in the chuck from all the way threaded in to out as far as they can go and still get the locking alen in.

Not sure what else to try.Thanks in advance for in info yall can provide.