- Joined

- Jan 22, 2014

- Messages

- 578

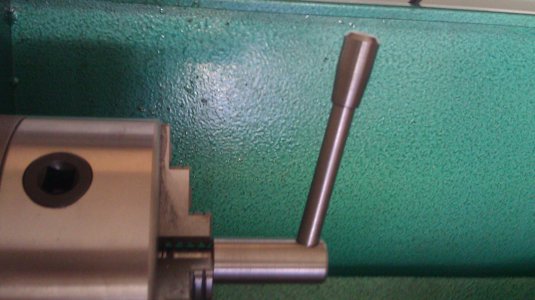

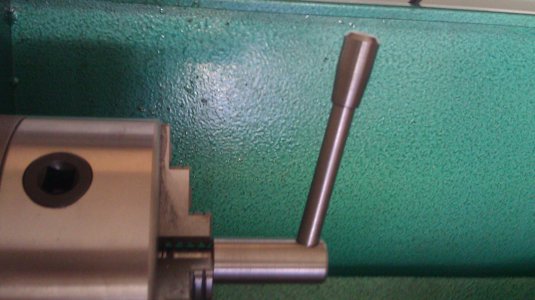

I wanted to upgrade my G0602 tail stock and so here's what I ended up doing. I started with a whim that maybe the Little Machine Shop kit may work. The lifting block and clamp work fine but the shaft & handle were too short, so I made a new one. I made a shaft extension that I bored and brazed the LMS kit shaft into it. Then I turned a new handle to match the Grizzly knobs and handles.