- Joined

- Feb 25, 2017

- Messages

- 58

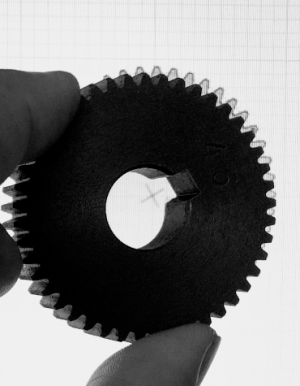

Rubbing is putting a piece of paper on top of the gear & lightly rubbing a pencil/piece of chalk over some gear teeth.

Same thing you would do with a headstone or monument with engraved names.

This should produce sharp edges, but the smaller the gear the harder it is.

When measuring the pressure angle draw a line from the start of the involute to where it hits the edge of the tooth. That should get you close.

Or just use a tangent line on the involute & eyeball it to the midpoint. I'd have to pull out machineries handbook or a gear book to get you better methods.

Or, like someone mentioned above, there are gear catalogs with various full sized gears for comparison.

Regards,

Steve

Same thing you would do with a headstone or monument with engraved names.

This should produce sharp edges, but the smaller the gear the harder it is.

When measuring the pressure angle draw a line from the start of the involute to where it hits the edge of the tooth. That should get you close.

Or just use a tangent line on the involute & eyeball it to the midpoint. I'd have to pull out machineries handbook or a gear book to get you better methods.

Or, like someone mentioned above, there are gear catalogs with various full sized gears for comparison.

Regards,

Steve

Really comes down to how many you'll be looking at. If you go this route then make sure the specs will allow you to get a few teeth in view.

Really comes down to how many you'll be looking at. If you go this route then make sure the specs will allow you to get a few teeth in view.