I started this 10 years before the Internet back then if you didn't know machinist you are on your own, all information came in magazines.

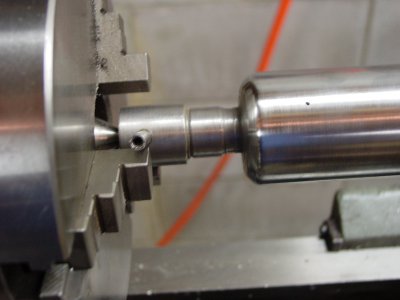

If you look at the attached photos,

I need to turn a ball on the end of this canon, at present it is between a live Center and a dead center and that would be the ideal place to do it. The other alternative is to make / buy a Mandrell and use a steady rest, I don't like the idea of the steady rest scratching up my finish. The canon has 1/2 inch bore.

Any suggestions would be appreciated.

If you look at the attached photos,

I need to turn a ball on the end of this canon, at present it is between a live Center and a dead center and that would be the ideal place to do it. The other alternative is to make / buy a Mandrell and use a steady rest, I don't like the idea of the steady rest scratching up my finish. The canon has 1/2 inch bore.

Any suggestions would be appreciated.