I've never used a carbide tap prior to this past weekend. I purchased a couple of press plates online with the idea of adding a ring on the bottom to captivate them on the press while allowing them to rotate if needed. I soon discovered that the 1" thick plates were also hardened. To what level I do not know, but a new cobalt drill bit would not make as much as a filing. No problem, I have an 1/8" carbide drill bit. I drilled a hole .700 deep, my idea called for a blind hole. I then opened the hole with carbide end mills, 1/4", then 5/16" (.3125) for a 3/8" cap screw. Then I discovered my tap wouldn't scratch it either. I wasn't having fun anymore. OK! Lets give the guy with anger issues a hardened plate, a blind hole, and a brittle tap and set him alone in the corner and watch what happens! My wife thinks this is hi entertainment when self quarantining.

I chose a WIDIA TiN coated carbide tap thinking it would look very nice broken off in the hole. $30 later, I had my eminent failure in hand. First thing I had overlooked was the fact that the tap had no flats to use with a tap wrench because your not supposed to use carbide taps for hand tapping apparently.

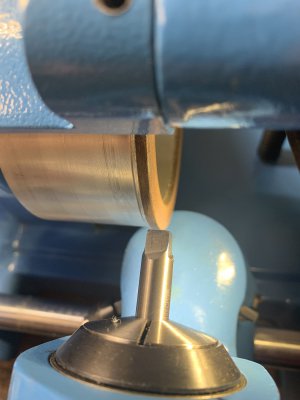

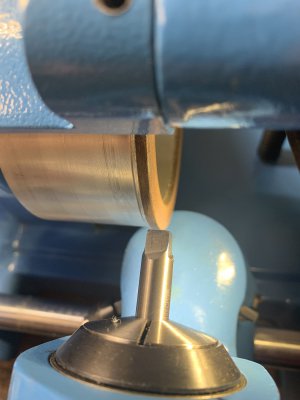

Wouldn't let that slow me down so I ground some flats on it using the universal grinder.

By now I've determined that this project was riding a bullet train, destination disaster. After consuming a little thinking juice (I usually have pretty good success with Miller Lite) I put a tap guide in the collet on the mill and decided to get started.

Resistance was high and cutting fluid seemed to provide little help. With 1/8 turns and then breaking the chip, I finally made it to the bottom. The bright threads happened as I believe the hole was flooded with sweat and cutting fluid.

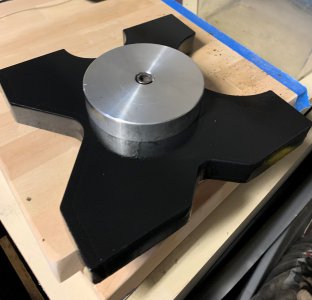

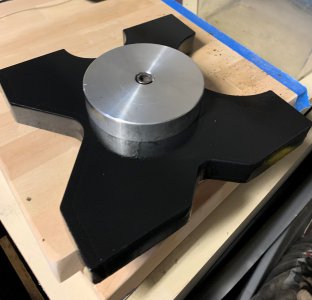

The resistance was present all the way down, so much that I had to keep checking to see if I had hit bottom of the blind hole. I would be really nervous using a carbide tap 1/4" or smaller. It did work though with a little patience and a lot of thinking juice. The ring on the bottom of the press plate allows for free rotation but most importantly can be removed if needed. I did both plates and surprisingly still have the tap.

I chose a WIDIA TiN coated carbide tap thinking it would look very nice broken off in the hole. $30 later, I had my eminent failure in hand. First thing I had overlooked was the fact that the tap had no flats to use with a tap wrench because your not supposed to use carbide taps for hand tapping apparently.

Wouldn't let that slow me down so I ground some flats on it using the universal grinder.

By now I've determined that this project was riding a bullet train, destination disaster. After consuming a little thinking juice (I usually have pretty good success with Miller Lite) I put a tap guide in the collet on the mill and decided to get started.

Resistance was high and cutting fluid seemed to provide little help. With 1/8 turns and then breaking the chip, I finally made it to the bottom. The bright threads happened as I believe the hole was flooded with sweat and cutting fluid.

The resistance was present all the way down, so much that I had to keep checking to see if I had hit bottom of the blind hole. I would be really nervous using a carbide tap 1/4" or smaller. It did work though with a little patience and a lot of thinking juice. The ring on the bottom of the press plate allows for free rotation but most importantly can be removed if needed. I did both plates and surprisingly still have the tap.