- Joined

- May 27, 2011

- Messages

- 49

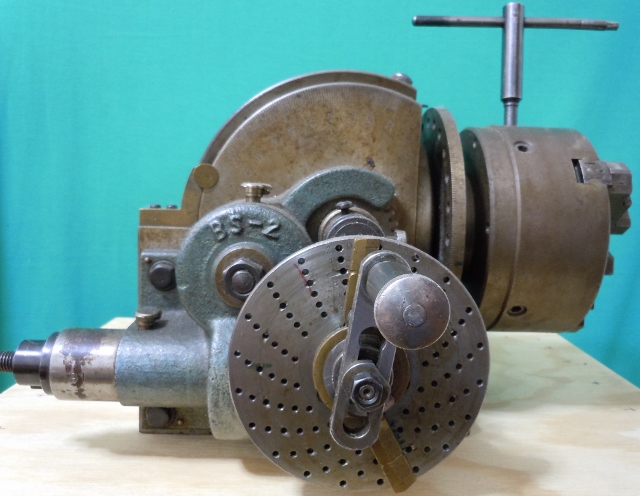

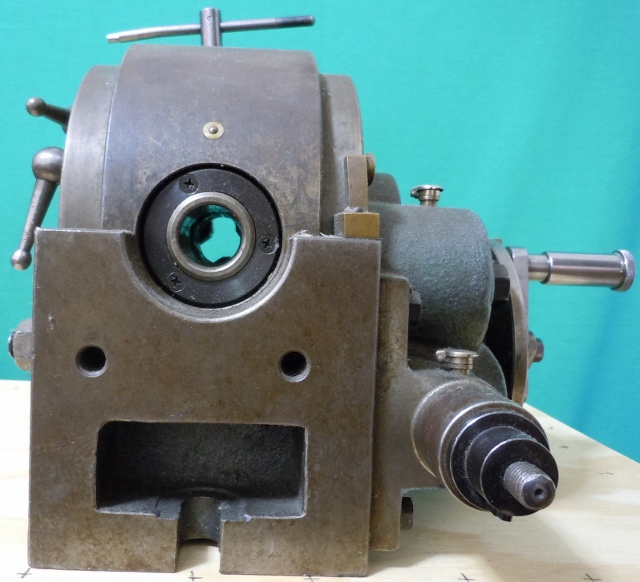

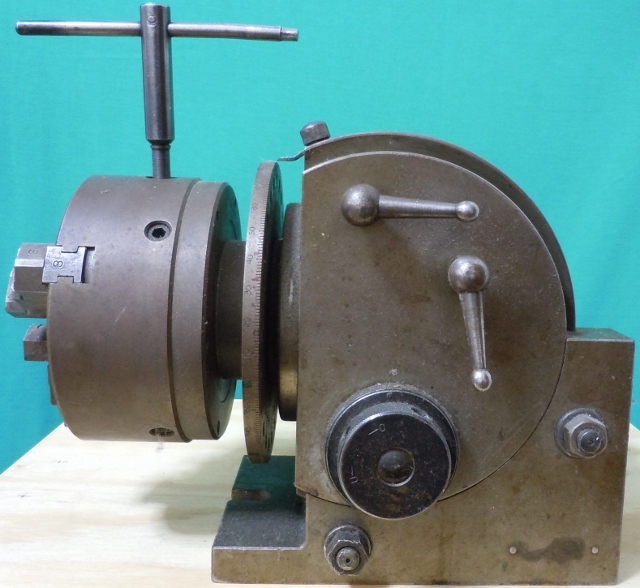

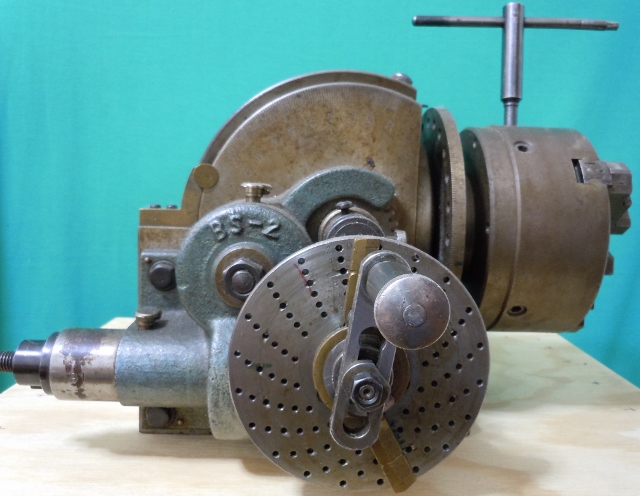

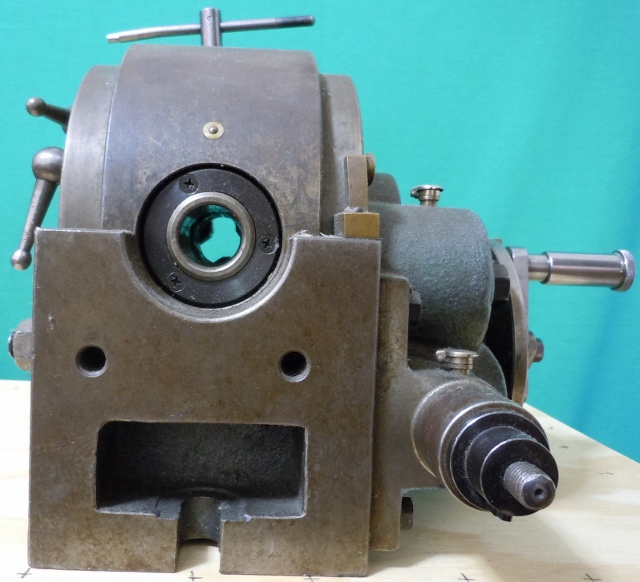

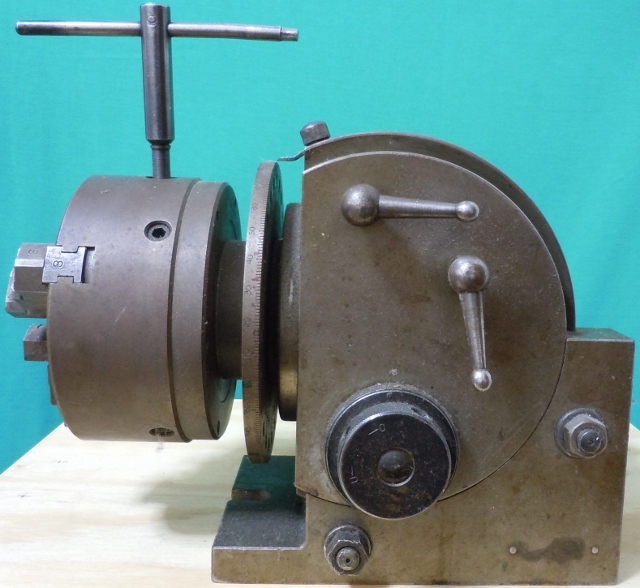

I confess I've never used a dividing head. This one was *gifted* to my shop complete with all the indexing plates and all the gears. My question: can I rotate the spindle while milling? There's no crank to rotate by hand....? I can see a lot of uses for this for indexing on the mill without using the table gear setup. I'd bet there's a youtube video on this . Thanks for any help...

. Thanks for any help...