Hello,

some of my tool holders came with CCMT 32.51 inserts. I am looking to buy some new inserts from a quality company and my toolholder company says any 300 series will fit.

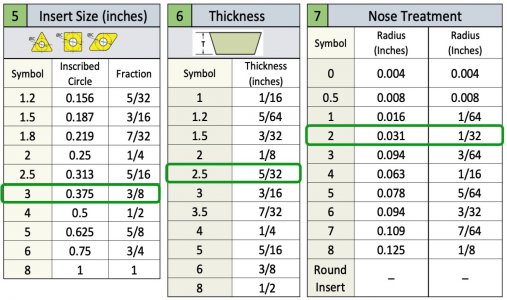

I do not understand the carbide insert numbering system, first off looking for 300 series is confusing and second what is the difference between 32.51 and 32.52?

What exactly does 300 series mean? I found 304, 321 and others but want to insure i purchase the correct fitting inserts as the price for Sandvik, Kenametal, Mistubishi is not cheap.

Any insight would be greatly appreciated

some of my tool holders came with CCMT 32.51 inserts. I am looking to buy some new inserts from a quality company and my toolholder company says any 300 series will fit.

I do not understand the carbide insert numbering system, first off looking for 300 series is confusing and second what is the difference between 32.51 and 32.52?

What exactly does 300 series mean? I found 304, 321 and others but want to insure i purchase the correct fitting inserts as the price for Sandvik, Kenametal, Mistubishi is not cheap.

Any insight would be greatly appreciated