- Joined

- Dec 8, 2016

- Messages

- 74

New to the milling world ,a bit overwhelmed to be honest but gingerly getting there . Tooling ,or lack of is my biggest bugbear up to date . I'm from an agricultural background so I'm making do for now .

Got myself some end mills ,face and side cutters ,a slitting saw blade . Done some modifications to the mill ,it's a very basic machine but I'm finding out very capable indeed . ..

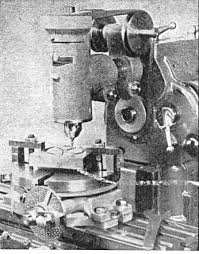

Here's the Centec 2 before and after a refurb ....

Got myself some end mills ,face and side cutters ,a slitting saw blade . Done some modifications to the mill ,it's a very basic machine but I'm finding out very capable indeed . ..

Here's the Centec 2 before and after a refurb ....