- Joined

- May 27, 2011

- Messages

- 49

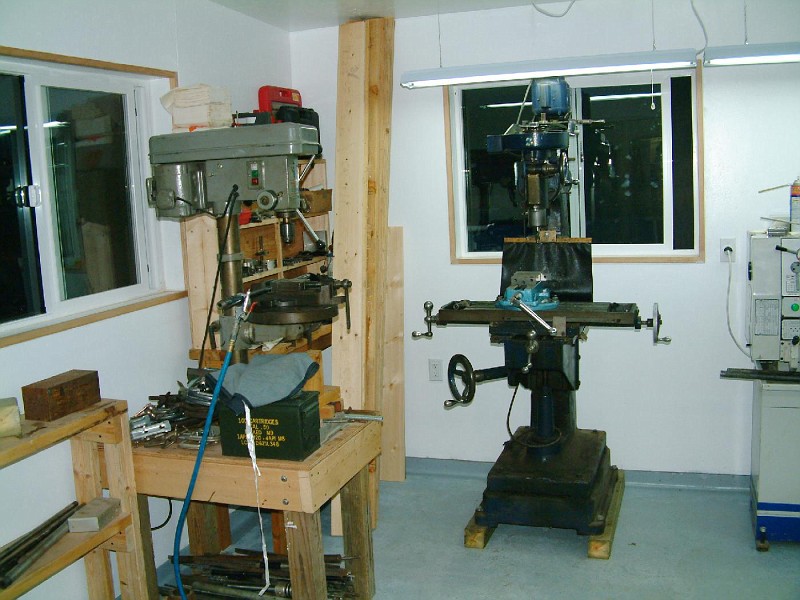

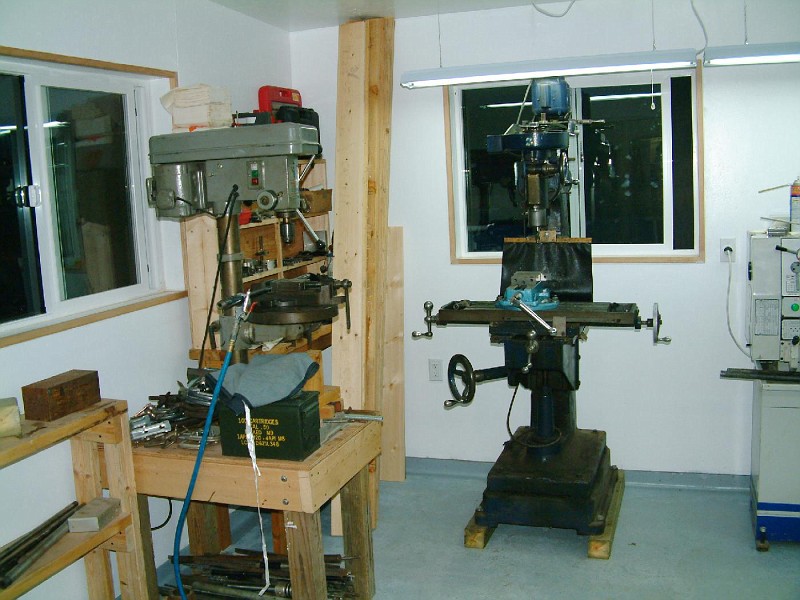

I bought this new in 1979 and I quickly learned you cannot drill a hole on the inside leg of angle iron. Drillbits don't like a slopping surface!! So I bent the spindle.

What to do? I pulled the quill out to have a look-see. The spindle has a 2MT spindle mount. The solution appeared to me as an epiphany.

I parted off the upper part of the spindle with the spline and thread, turned a tenon on the end. Then I lathe turned a new solid spindle with a 1/2-20 spindle nose for a 1/2" Jacobs medium duty sleeve chuck. At the other end I bored a hole for the spline part, pinned it in place with a 1/4" pin and silver soldered it in place. Put it all back together and turned it on. Bingo! Smooth running with zero wobble. Ran at 3,000+ with nary a problem. Its been running ever since with the only thing I've done to this drillpress is replace the belt and that was after 20+ years.

The threaded portion of the spindle is for thrust bearing take-up.

Say what you will about Chinese junk but this machine tool has been in use for 44 years.

Lots of these type drillpress in use. I'm betting a lot of them show spindle wobble. This repair/upgrade I did was really pretty easy and greatly improved the utility of the machine. The original spindle with a 2MT hole in it just doesn't have enough *meat* to support its use. And being soft low carbon steel doesn't help.

p.s. old mill is Index model 40 no longer in possession.

Dutch

What to do? I pulled the quill out to have a look-see. The spindle has a 2MT spindle mount. The solution appeared to me as an epiphany.

I parted off the upper part of the spindle with the spline and thread, turned a tenon on the end. Then I lathe turned a new solid spindle with a 1/2-20 spindle nose for a 1/2" Jacobs medium duty sleeve chuck. At the other end I bored a hole for the spline part, pinned it in place with a 1/4" pin and silver soldered it in place. Put it all back together and turned it on. Bingo! Smooth running with zero wobble. Ran at 3,000+ with nary a problem. Its been running ever since with the only thing I've done to this drillpress is replace the belt and that was after 20+ years.

The threaded portion of the spindle is for thrust bearing take-up.

Say what you will about Chinese junk but this machine tool has been in use for 44 years.

Lots of these type drillpress in use. I'm betting a lot of them show spindle wobble. This repair/upgrade I did was really pretty easy and greatly improved the utility of the machine. The original spindle with a 2MT hole in it just doesn't have enough *meat* to support its use. And being soft low carbon steel doesn't help.

p.s. old mill is Index model 40 no longer in possession.

Dutch