- Joined

- Sep 22, 2013

- Messages

- 66

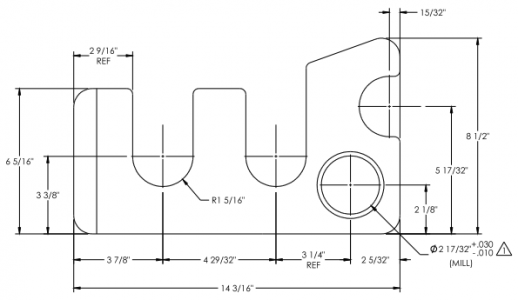

I received an RFQ for a part with a 2 17/32" hole that needs to be bored to size and then add a 3/16" X 45 deg. chamfer. This will be done on my Bridgeport (non-CNC). The bore is straight-forward, but the chanfer has me befuddled. I had thought I could just find a boring bar that held a square insert at 45 deg, but that has been a fruitless search, so far. If such a bar doesn't exist, one thought I had was to use a fly-cutter and make my own 45 deg. bit for it (not something I've ever done).

My inexperience is showing here and I guess I need advice (or a head-slap) as to the best way to do this. Does the boring bar I envision exist? Am I missing some far easier method?

My inexperience is showing here and I guess I need advice (or a head-slap) as to the best way to do this. Does the boring bar I envision exist? Am I missing some far easier method?