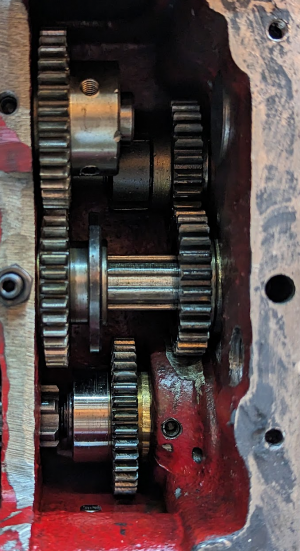

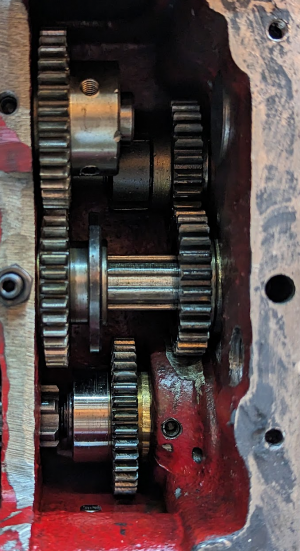

Since I had the gearbox open to clean it I decided to characterize it as completely as I can. I needed to do some of this to put it together correctly, and while I am about to convert to an electronic lead screw almost certainly driving this lathe for the rest of its life in ATW1 configuration (the maximum mechanical advantage, driving both the feed bar and lead screw), others might find this more useful.

A/B set the ratio of a:b

C sets the ratio of a:d

R/S/T set the ratio of b:c which is either unity (1:1 or 19:38 in one direction or the other):

1-8 set the ratio of c:d

W couples d:e 36:35 (1.0285) and e:f is permanently coupled 26:26 (unity)

Y couples b:e 35:35 (unity) and e:f is permanently coupled 26:26 (unity)

20/50 * 19/38 * 24/33 = 9120/62700 = 456/3135 = 8/55 ~= .1454 (feed bar)

8/55 * 36/35 = 288/1925 ~= .1496 (lead screw)

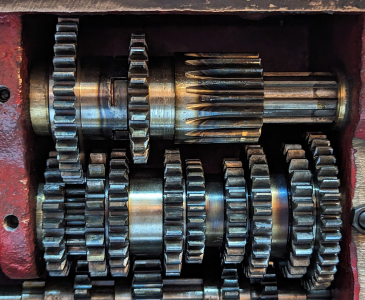

Rotational domain definition

The manual doesn't have names for this, so I have to make something up. There are six independent axes of rotation in the gearbox. The gearbox is driven from the change gears on the left, and drives both the lead screw at the top right and the feed screw at the bottom left. I'll call these independent axes "rotational domains" and refer to them with lower-case letters a-f, since upper-case letters and numbers are both used for settings. They aren't labeled strictly in order, because different configurations drive them in different orders.

- Zone a: Input from the change gears; terminates at the first divider

- Zone b: The entire topmost axis, through both dividers

- Zone c: Coaxial with zone a, but terminating on each side at the dividers

- Zone d: Connected from wall to wall; holds a driving gear from a engaged only in the C configuration, a series of four gears that engage with 8 of the 10 gears in zone c selected by the 1-8 setting cam at the bottom, an output gear to the right of the rightmost divider, and finally directly drives the feed bar out the right side.

- Zone e: Coaxial with zones a and c, has one sliding gear that couples b to f (Y configuration), leaves f uncoupled (X configuration; drives only feed bar not lead screw), or couples d to f (W configuration)

- Zone f: The lead screw output

Driving Orders

The A/B/C and W/X/Y selectors affect the order in which the domains are driven. I denote x driving y as x→y here.- A/B: a→b→c →d

- C...Y: a→d→c →b→e→f (used only for the lead screw; in these configurations the feed bar turns at the same rate relative to the input regardless of R/S/T or 1-8 settings)

- W: d→e→f

- X: Drives only the feed bar (direct from d) without engaging the lead screw at all)

- Y: Used only with C to drive only the lead screw (b→e→f)

Driving Ratios

The A/B/C, R/S/T, W/Y, and 1-8 selectors choose gear ratios. The direction in which those ratios apply from input to output depends on the driving order selectors previously described. I use the actual gear tooth counts here and do not reduce ratios to "proper fractions". This should help look up the gears in the manual and follow along.A/B set the ratio of a:b

| a | b | decimal | |

|---|---|---|---|

| A | 20 | 50 | 0.4 |

| B | 19 | 19 | 1.0 |

C sets the ratio of a:d

| a | d | decimal | |

|---|---|---|---|

| C | 19 | 22 | 0.8636 |

R/S/T set the ratio of b:c which is either unity (1:1 or 19:38 in one direction or the other):

| b | c | decimal | |

|---|---|---|---|

| R | 38 | 19 | 2.0 |

| S | 23 | 23 | 1.0 |

| T | 19 | 38 | 0.5 |

1-8 set the ratio of c:d

| c | d | decimal | |

|---|---|---|---|

| 1 | 24 | 33 | 0.7575 |

| 2 | 27 | 33 | 0.8181 |

| 3 | 20 | 22 | 0.9090 |

| 4 | 22 | 22 | 1.0 |

| 5 | 23 | 22 | 1.0454 |

| 6 | 24 | 22 | 1.0909 |

| 7 | 26 | 22 | 1.1818 |

| 8 | 28 | 22 | 1.2727 |

W couples d:e 36:35 (1.0285) and e:f is permanently coupled 26:26 (unity)

Y couples b:e 35:35 (unity) and e:f is permanently coupled 26:26 (unity)

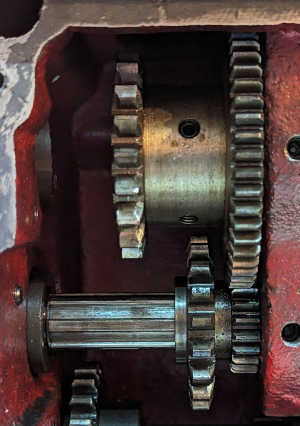

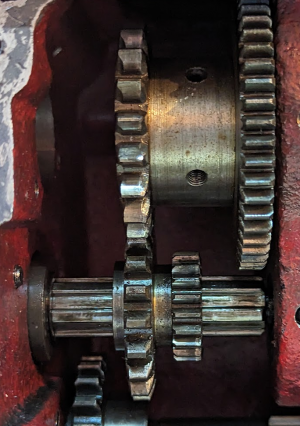

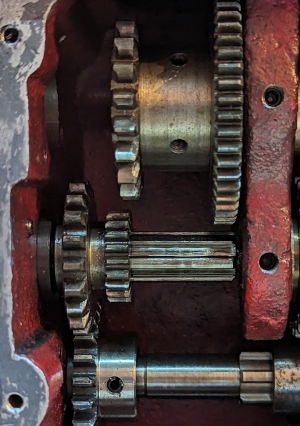

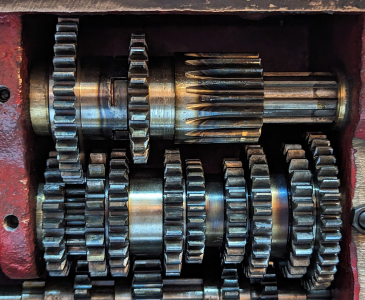

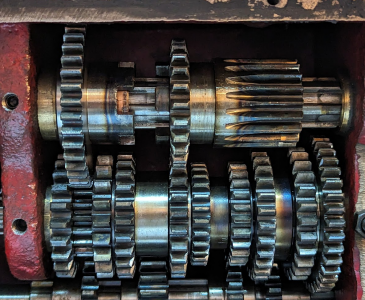

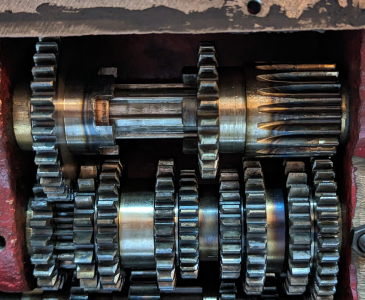

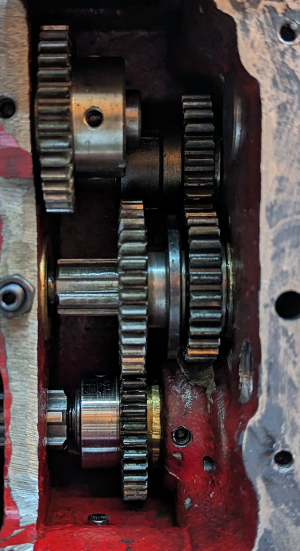

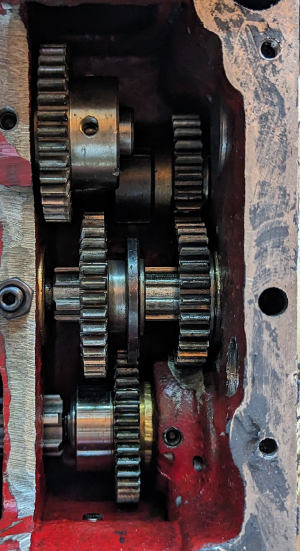

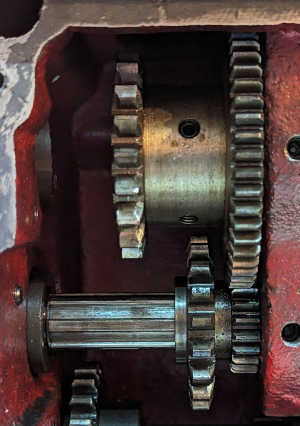

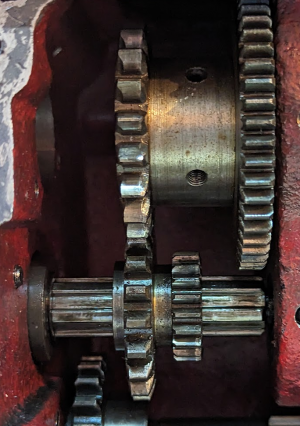

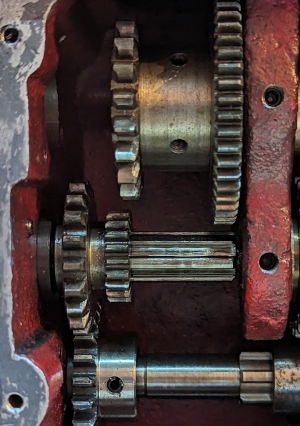

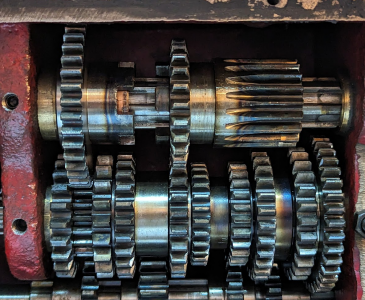

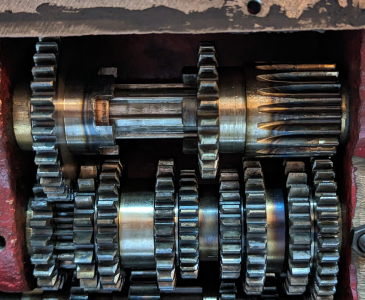

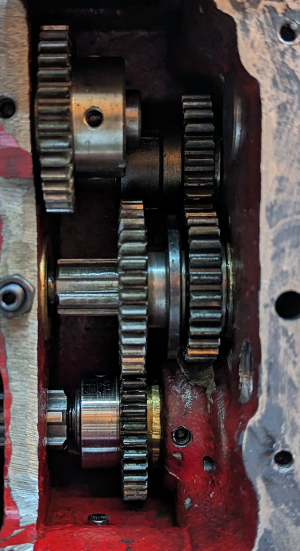

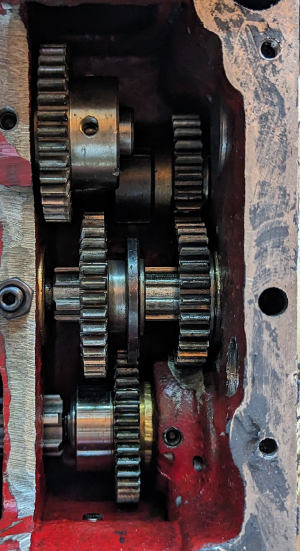

Configuration Close-ups

Here are pictures of the relevant section of the gearbox for each separate configuration option, with some description.A/B/C Selector

A

Input a coupled to b domain 20:50

B

Input a coupled to b domain 19:19

C

Input a coupled to d domain 19:22

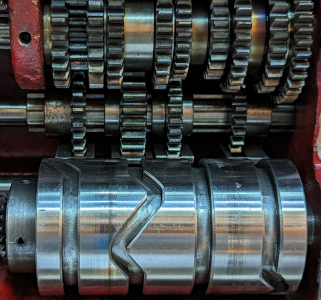

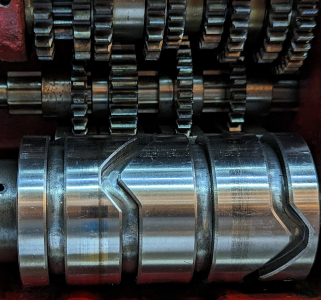

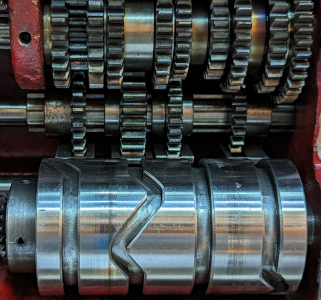

R/S/T Selector

R

Note that the 38:19 pair are always engaged with each other; in position R, a castellated pair couples the spline of axis b to the otherwise freely-rotating 38-tooth gear at the top left of this picture.

S

Here, the castellations are disengaged, leaving the 38-tooth gear as an idling gear driven by axis c, but coupling b:c at unity through a pair of 23-tooth gears.

T

Here, the long 19-tooth gear at the right on axis b engages a 38-tooth gear on axis c.

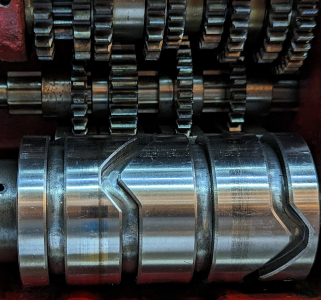

W/X/Y Selector

The W/X/Y selector determines which domain, if anym drives the lead screw.W

The d domain drives the lead screw

X

The e domain is disengaged, and the lead screw is not driven

Y

The b domain drives the lead screw

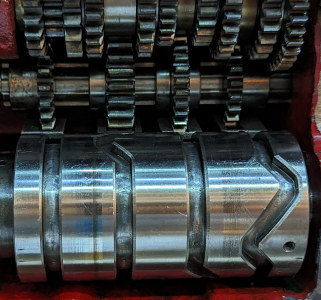

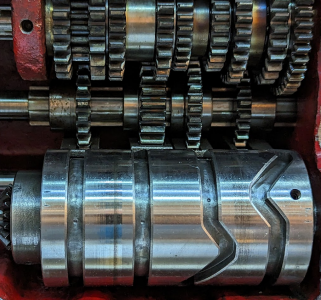

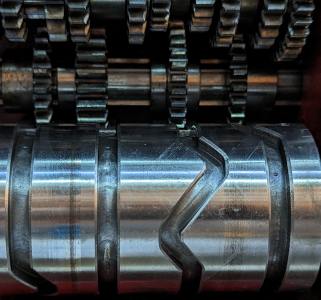

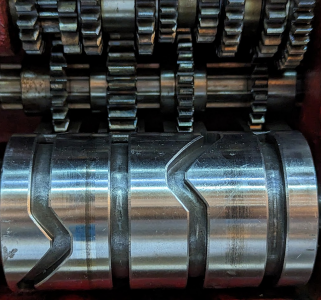

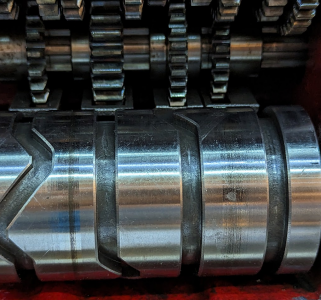

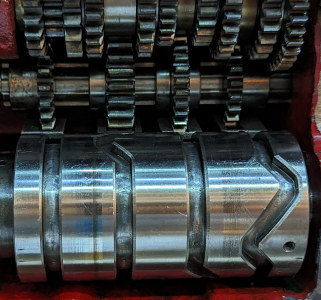

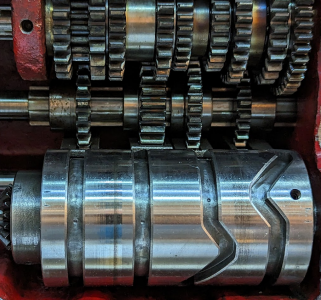

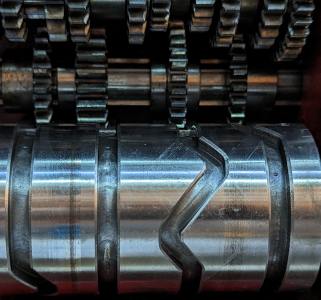

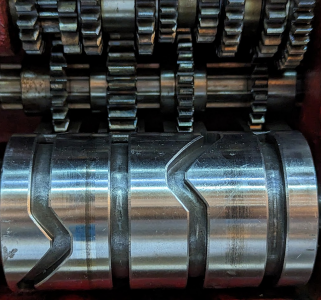

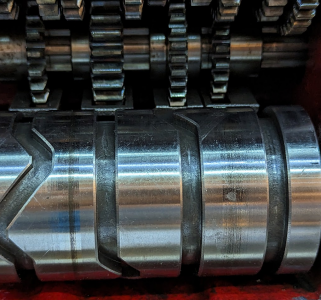

1-8 Selector

When reassembling the gear box, one of the trickiest bits is to make sure that the number selector is correct.1

24:33

2

27:33

3

20:22

4

22:22

5

23:22

6

24:22

7

26:22

8

28:22

Worked Example

ATW1 means (input) a→b 20:50 b→c 19:38 c→d 24:33 (feed bar) d→e 36:35 e→f 26:26 (lead screw)20/50 * 19/38 * 24/33 = 9120/62700 = 456/3135 = 8/55 ~= .1454 (feed bar)

8/55 * 36/35 = 288/1925 ~= .1496 (lead screw)