- Joined

- Jan 2, 2019

- Messages

- 6,538

Hi,

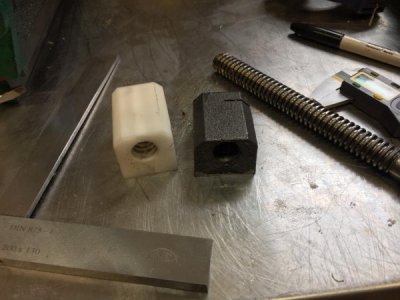

I'm trying to improve a Chinese X-Y table and was looking for a way to reduce backlash. Just wondering if anyone has done something like this guy does in his video? If so, what kind of plastic would you use, I have a suitable piece of delrin that might work if the properties are right.

Thanks,

John

I'm trying to improve a Chinese X-Y table and was looking for a way to reduce backlash. Just wondering if anyone has done something like this guy does in his video? If so, what kind of plastic would you use, I have a suitable piece of delrin that might work if the properties are right.

Thanks,

John