- Joined

- Jan 20, 2018

- Messages

- 5,684

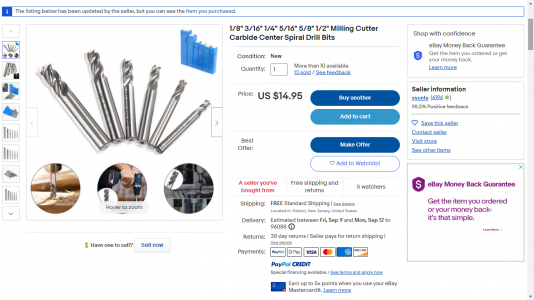

I stumbled across this assortment of end mills a few days ago. Scarcely believing my eyes (or the ad), but willing to gamble, I ordered them.

I mean really, 6 end mills for $16 delivered, what could possibly go wrong?

They arrived yesterday.

First, they are not carbide (I knew they weren't, it says HSS in the text of the listing) and there is no 5/8", it's a 3/8".

On checking them out, they are literally ±.002 for size.

They are 4-flute, not center cutting.

They do cut steel, at least the 1/4" I tried did. It cut smoothly and left a nice finish.

No clue or claims as to how they might hold up.

YMMV

I mean really, 6 end mills for $16 delivered, what could possibly go wrong?

1/8" 3/16" 1/4" 5/16" 5/8" 1/2" Milling Cutter Carbide Center Spiral Drill Bits | eBay

6PCS HSS 4 Flute End Mill Cutter Milling Cut Bit 1/8" 3/16" 1/4" 5/16" 5/8" 1/2".

www.ebay.com

They arrived yesterday.

First, they are not carbide (I knew they weren't, it says HSS in the text of the listing) and there is no 5/8", it's a 3/8".

On checking them out, they are literally ±.002 for size.

They are 4-flute, not center cutting.

They do cut steel, at least the 1/4" I tried did. It cut smoothly and left a nice finish.

No clue or claims as to how they might hold up.

YMMV