I am new to machine work. Took the plunge by the way of grabbing a smithy at a very low price.

I am new to machine work. Took the plunge by the way of grabbing a smithy at a very low price.I have also acquired some tooling, measuring devices and many other odds and ends. One of which is. Bison 5” 4 jaw ind. chuck.

So after a few small projects im going to dive in and attempt to make a plate to adapt this unit.

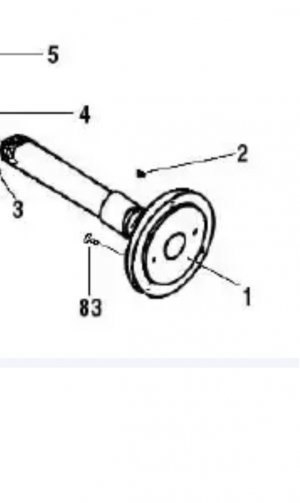

Its a tad small for the smithy. So I need to make a plate that bolts to the smithy spindle ( 3 hole) and then the bison mounts with 4 bolts from the front.

Posting pictures on this forum is painful so there wont be to many all to soon