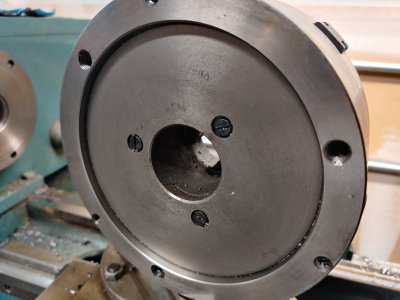

I have an Enco 110 (but not like all the other Enco 110 lathes), and I'm wondering if there's any way to make an educated guess on the spindle and back plate. I took the chuck off, and the shoulder on the back plate is very close to 130mm; I couldn't really tell about the spindle, but it looks like it could be threaded?

I was under the understanding that threaded back plates aren't common and/or recommended in lathes that run in reverse (and this one does), but does that simply mean I'm not supposed to CUT in reverse, or...?

I was under the understanding that threaded back plates aren't common and/or recommended in lathes that run in reverse (and this one does), but does that simply mean I'm not supposed to CUT in reverse, or...?