- Joined

- Apr 30, 2015

- Messages

- 11,372

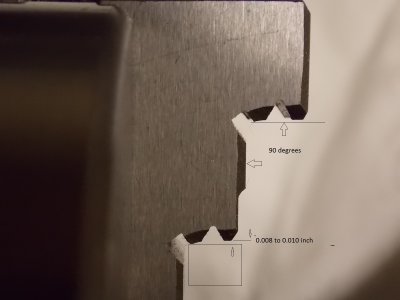

I'm currently going back and forth with Shars concerning a poorly made set of jaws. It seems they use inverted terms than I do- what do you call this type of jaw (picture)? They call these "internal jaws" for reasons I don't understand. Aren't these used for grasping the outside of cylindrical workpieces? Therefore "external" jaws? Who is correct here, and what is the other standard or "jamming" set called?

I'm currently going back and forth with Shars concerning a poorly made set of jaws. It seems they use inverted terms than I do- what do you call this type of jaw (picture)? They call these "internal jaws" for reasons I don't understand. Aren't these used for grasping the outside of cylindrical workpieces? Therefore "external" jaws? Who is correct here, and what is the other standard or "jamming" set called?Mark S.