- Joined

- Jan 7, 2016

- Messages

- 5

Hello,

Have been researching my options to install the QCTP (Aloris style one) to my Clausing 100 Mk3. I do have original tool post with some tool holders as well as some modified 4 way tool post but it is really inconvenient. I'm kind of lost as different sources say that size of Aloris I need is AXA but others say BXA is needed. Does somebody has the hands on experience with the matter?

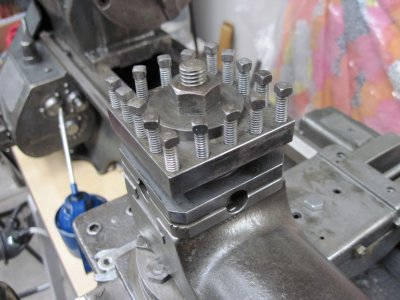

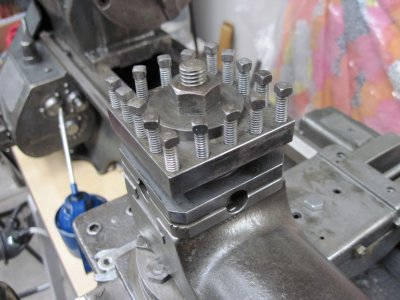

If somebody is interested there are few pics:

There are only 8 positions to this tool post and there is no "free" position because of the way base is attached to the nut. And balls (there are 4 of those) are way to big so top has to be raised a lot in order to be able to turn it.

Thanks,

Ab

Have been researching my options to install the QCTP (Aloris style one) to my Clausing 100 Mk3. I do have original tool post with some tool holders as well as some modified 4 way tool post but it is really inconvenient. I'm kind of lost as different sources say that size of Aloris I need is AXA but others say BXA is needed. Does somebody has the hands on experience with the matter?

If somebody is interested there are few pics:

There are only 8 positions to this tool post and there is no "free" position because of the way base is attached to the nut. And balls (there are 4 of those) are way to big so top has to be raised a lot in order to be able to turn it.

Thanks,

Ab