- Joined

- Apr 10, 2021

- Messages

- 593

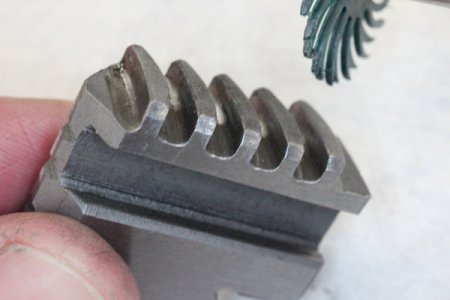

I've been watching for eithe Buck Adjust tru or Bison set tru 12" chuck for my Monarch 16" lathe. I have a 12" independent and a 10" Bison combination four jaw which is my go to chuck. I don't have a very good three jaw so I've been watching for a three or six jaw but not wanting to cough up $3000 for something I don't need often. Over the past year I found a couple of D1-6 backplates for under $150 as finding a chuck with the correct plate is like winning the lottery without buying a ticket. Recently I found a listing for a six jaw chuck off a Haas CNC machine. The chuck wasn't labeled but I knew from the numbers that is was a 12" Bison Set Tru. My concern was that the guts of the chuck might be rusted from coolant from a CNC so I offered $800 unless the seller was willing to take the chuck apart and show the inside. Got the chuck and it did have some rust on the gear side of the scroll. Bathed it in evaporust and cleaned everything up.

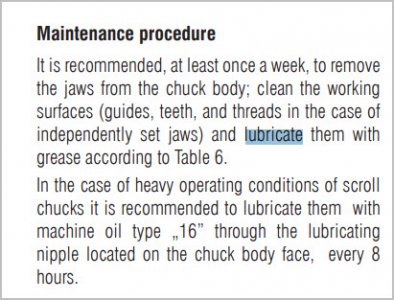

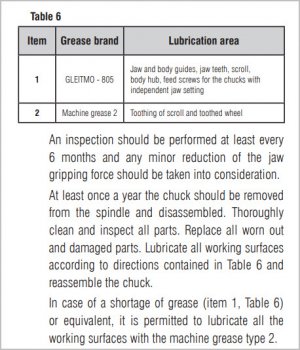

My question - finally - is how to lubricate. I'll use oil on the scroll and jaws but wondering of some type of grease might be better on the gear side. It is shielded from most chips but I'd like opinions on what makes the most sense.

Dave

My question - finally - is how to lubricate. I'll use oil on the scroll and jaws but wondering of some type of grease might be better on the gear side. It is shielded from most chips but I'd like opinions on what makes the most sense.

Dave