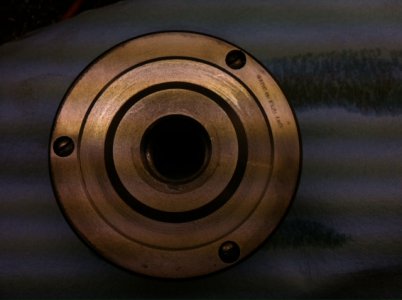

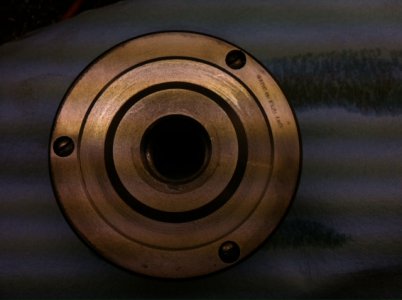

Guys I could use some help please. I have a hard spot in my chuck when tighting the jaws that developed after cutting some brass. Im just guessing that there is a chip in it. I looked at some other posts in general questions with the same problem. So this weekend I tried to take mine apart, couldn't. Could I get some help on this please. I took the jaws out then removed the 3 screws and couldn't get it apart. Heres some pics of the chuck.

TIA Vince

TIA Vince